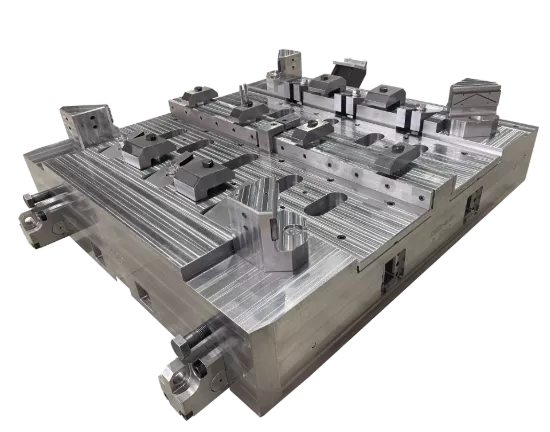

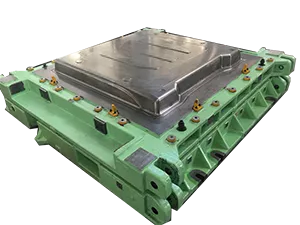

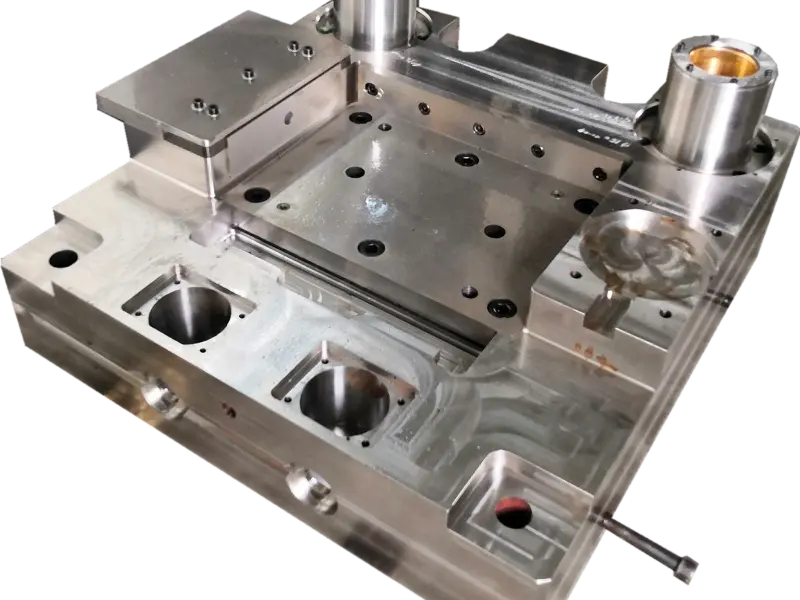

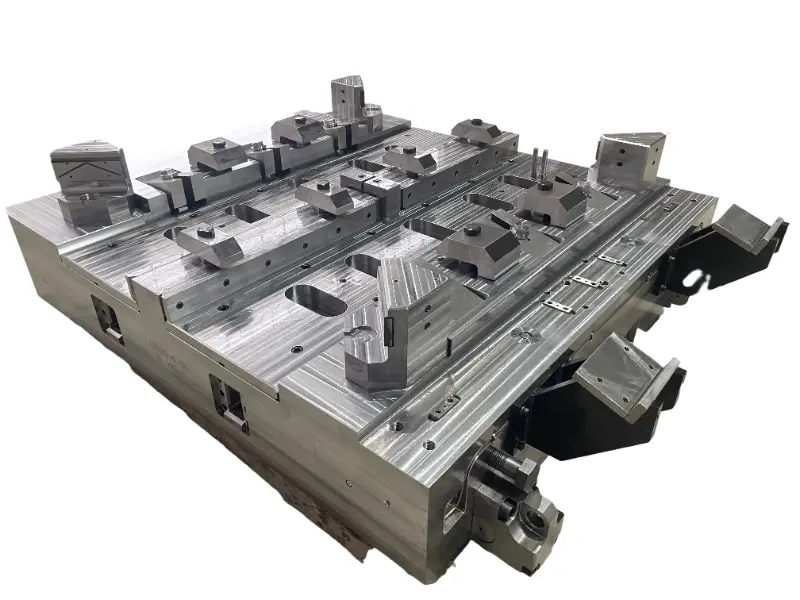

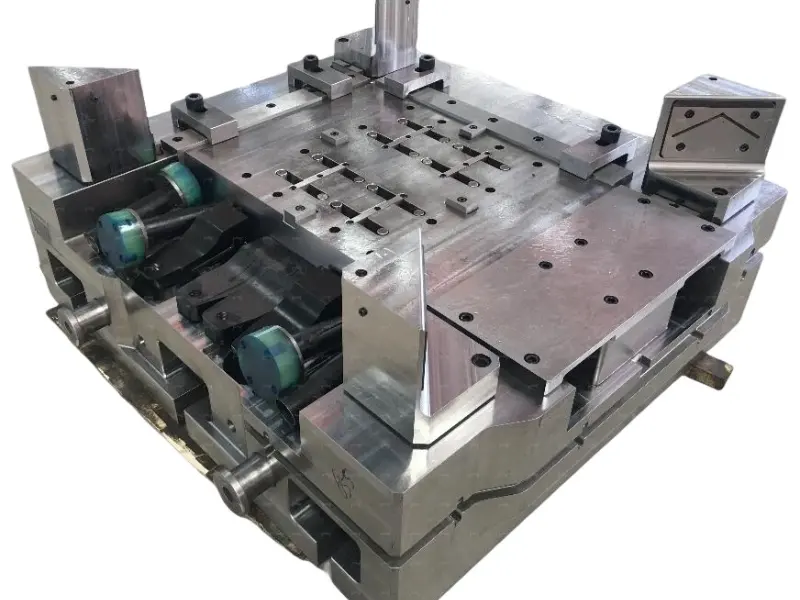

Used on large forging equipment, using forging equipment with a capacity of 350T or more,The type of forging equipment is:Free Forging Hydraulic Press,Die Forging Hydraulic Press,Screw Press,Hot Die Forging Press,Multi-Directional Forging Hydraulic Press.The forging die Set, as the core connecting component between forging equipment and molds, is a key basic component that ensures stable and efficient forging processes. It directly affects the forming accuracy, mold life, and production safety of forgings by accurately positioning the mold, uniformly transmitting pressure, and withstanding severe impact and high temperature loads. It is widely used in various forging process scenarios such as free forging, die forging, and hot forging.

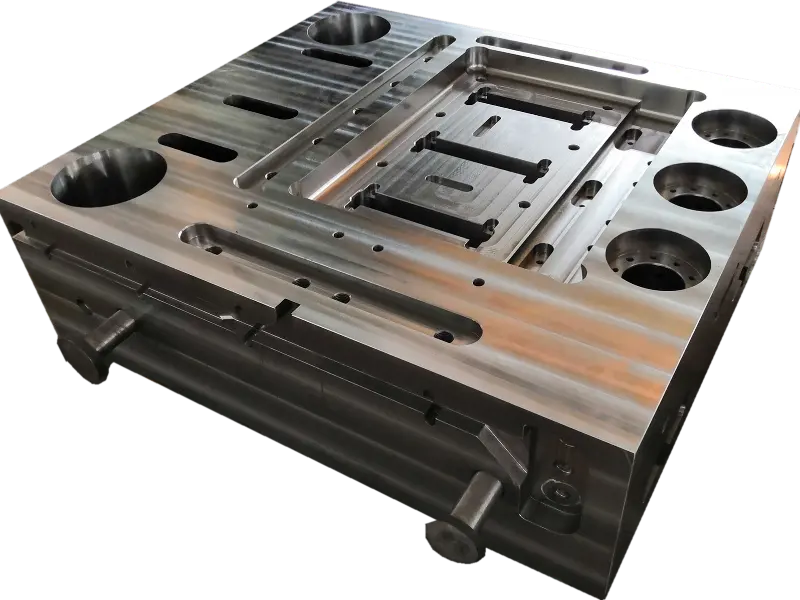

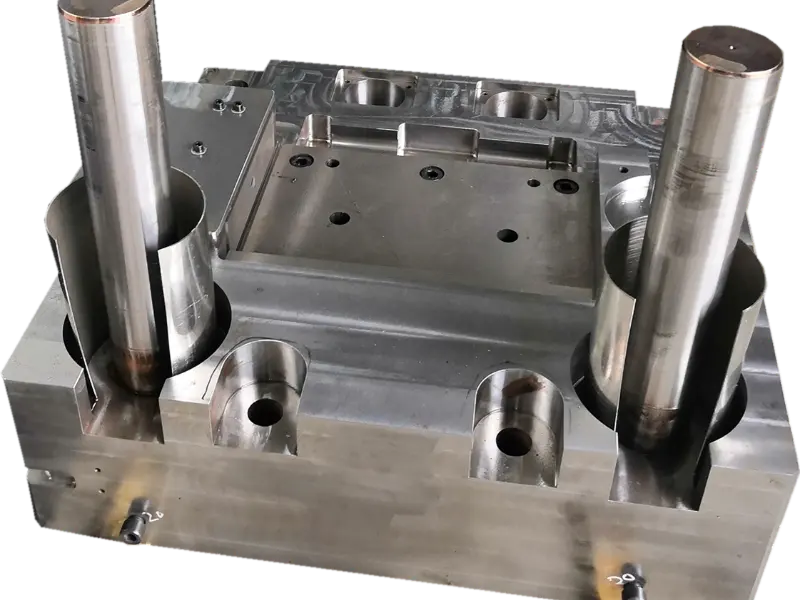

350T-3500T Forging Mold Frame

steel: 1.2714 / 56NiCrMoV7 / 40CrNiMoA /5CrNiMo, etc.

Product Description:

Product Usage

In forging production, the forging Mold Frame provides a rigid installation reference for the upper and lower molds, ensuring that the molds are not offset under high pressure and guaranteeing the dimensional consistency of complex forgings (such as automobile crankshafts and aviation engine blades); During the operation of hot forging press, its excellent heat resistance can reduce deformation caused by repeated high-temperature impacts and extend the mold replacement cycle; For specialized molds used with large free forging hydraulic presses, the die set can evenly distribute the pressure of tens of thousands of tons to the working surface of the mold, avoiding mold cracking caused by local stress concentration. In addition, on the multi-directional forging hydraulic press, the customized die set can adapt to multi-directional force molds, meeting the complex forming requirements of irregular forgings.