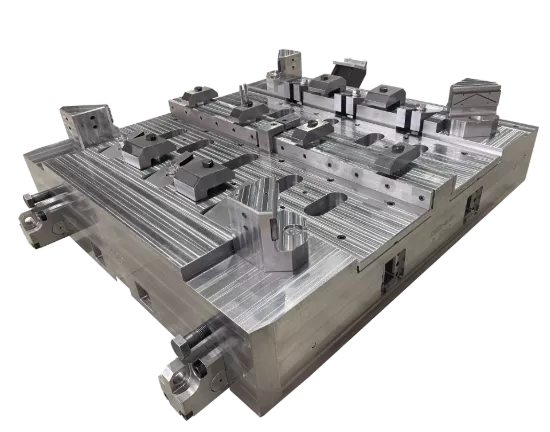

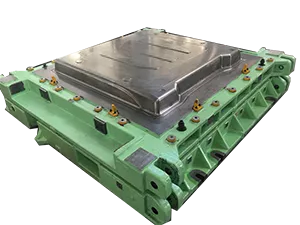

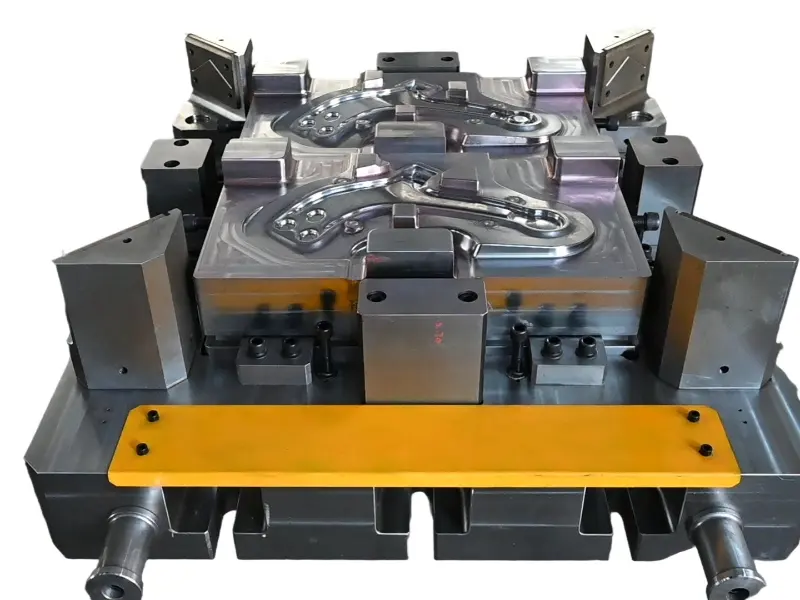

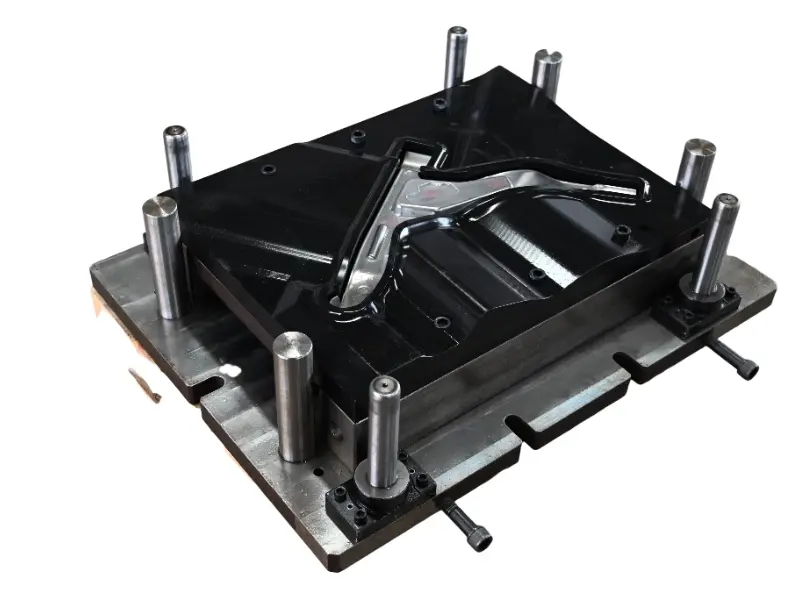

Aluminum alloy forging dies are tools used to produce aluminum alloy forgings. The products that can be forged are widely used in various fields such as automobiles, aerospace, electronics, machinery, etc., such as engine cylinder blocks, cylinder heads, pistons, connecting rods, steering knuckles, control arms, wheel hubs, etc. Aluminum alloy forging dies are composed of roll forging dies, pre forging dies, final forging dies, and edge cutting dies. Through the compression of different dies, qualified aluminum forging products are finally produced.

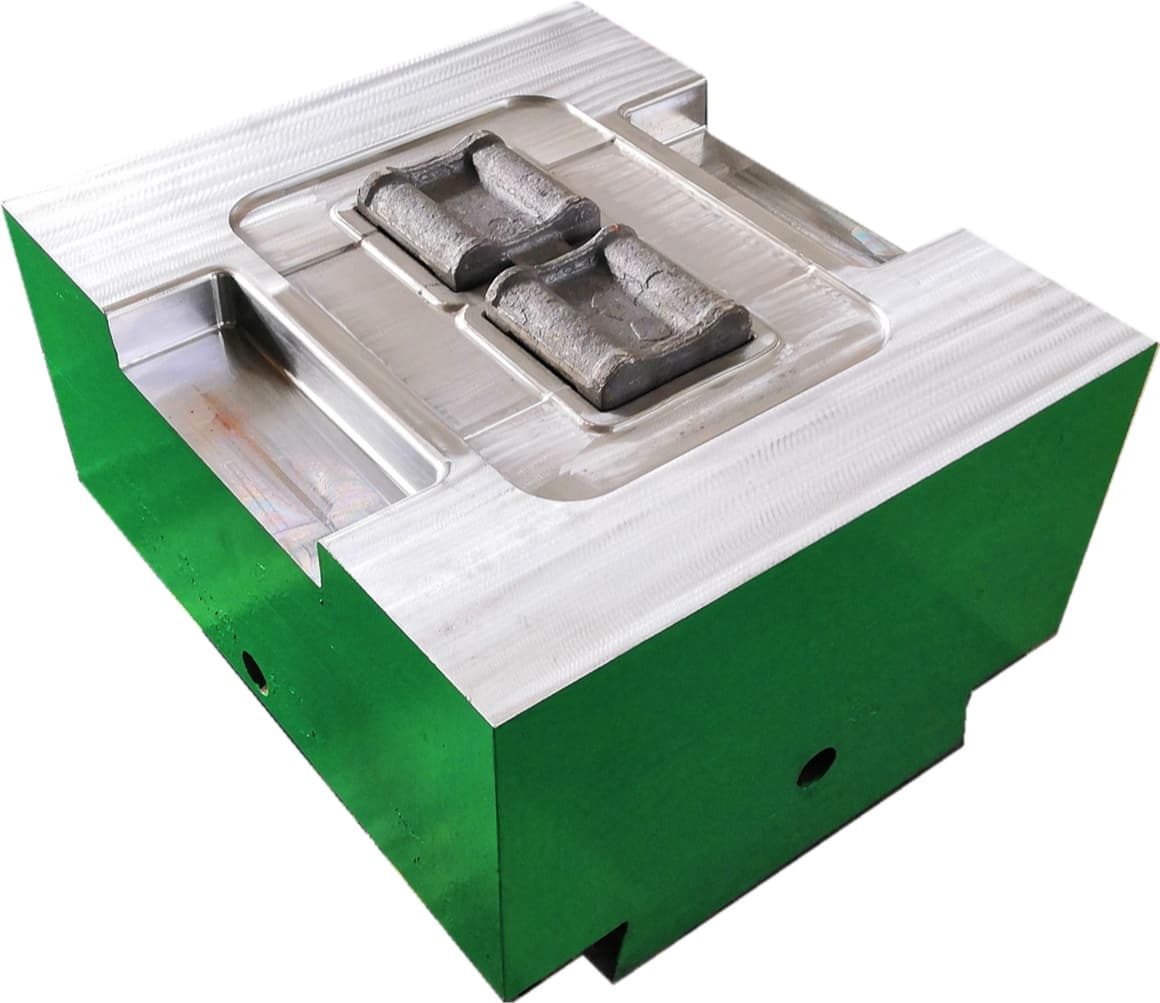

Aluminum alloy forging mold

steel: 1.2714, 1.2365 , H13, 5CrNiMo, 5CrNiMoV ,40CrNiMoA, etc.

Product Description:

Product Usage

Aluminum alloy forging molds are tools used to produce aluminum alloy forgings. The products that can be forged are widely used in various fields such as automobiles, aerospace, electronics, machinery, etc., such as engine cylinder blocks, cylinder heads, pistons, connecting rods, etc. The good thermal conductivity and lightweight characteristics of aluminum alloy help improve engine heat dissipation efficiency, reduce vehicle weight, thereby enhancing fuel economy and power performance, steering knuckles, control arms, wheel hubs, etc. Forged aluminum alloy wheels are not only lightweight, reducing unsprung mass and improving vehicle handling performance, but also have high strength and good toughness, capable of withstanding various complex stresses during vehicle operation. The steering knuckles and control arms are made of aluminum alloy forging, which can reduce weight, improve vehicle comfort and stability while ensuring strength.