Beginner’s Guide: 10 Simple Steps to Mastering Stamping Die Use

Release time: 2025-11-26

Table of Contents

Stamping dies are indispensable tools in modern manufacturing, widely used in automobiles, home appliances, electronics, and many other fields. For beginners, mastering the use of stamping dies can not only improve production efficiency but also effectively reduce costs. However, many people may feel confused when first encountering stamping dies. This guide will introduce 10 simple steps to help beginners quickly get started and master the use of stamping dies.

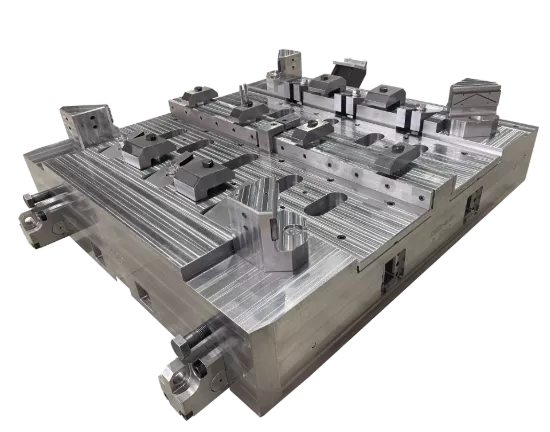

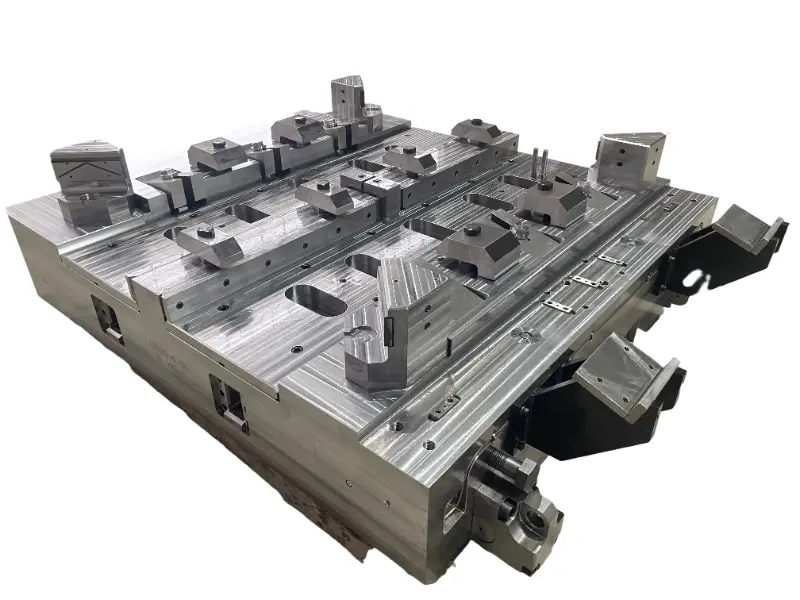

Understanding the Basic Concepts of Stamping Dies

A stamping die is a tool that uses pressure to plastically deform metal sheets, thereby achieving the desired shape. It typically consists of an upper die, a lower die, and die accessories, and can be used for shearing, forming, deep drawing, and other processing operations. Understanding the basic structure and working principle of dies is the first step in using stamping dies.

Choosing the Right Stamping Die Material

The choice of material for stamping dies directly affects the die’s service life and processing accuracy. Common die materials include alloy steel, high-speed steel, and carbon steel. Choosing the right material can effectively improve the die’s durability and processing results.

Familiarize Yourself with Stamping Machine Operation

A stamping machine is a device that performs stamping operations. Understanding the working principles, operating methods, and safety precautions of a stamping machine is crucial for ensuring smooth stamping operations. For beginners, it is best to practice under the guidance of experienced technicians.

Configure and Install Dies

The installation of stamping dies requires precise adjustment to ensure the stability of the die’s connection with the machine tool. During installation, pay special attention to the die’s positioning, balance, and fixation to avoid machining problems caused by deviations.

Adjust Die Pressure

The working pressure of the stamping die needs to be adjusted according to the thickness of the material being processed and the die design. Beginners should master the appropriate pressure through practice. Excessive pressure may damage the die, while insufficient pressure may result in incomplete processing.

Inspect the Wear of Stamping Dies

With continued stamping operations, even durable stamping dies may gradually wear down. Regularly inspecting the die’s wear can help identify potential problems early, preventing impacts on product quality and production efficiency. When wear is severe, the die needs to be reground or replaced.

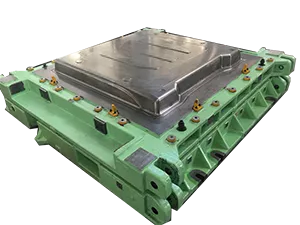

Understanding Die Maintenance

Die maintenance is crucial for extending its lifespan. Regularly cleaning the die, checking its lubrication system, and avoiding overload during stamping all effectively improve the die’s durability and machining accuracy.

Conducting Stamping Tests

Before formal production, conducting stamping tests helps determine the rationality of the die design and the smoothness of operation. Through testing, problems can be identified and adjusted, ensuring stability and product quality during mass production.

Controlling Temperature During Production

During the stamping process, temperature has a significant impact on die life and product quality. Excessively high temperatures can lead to die surface fatigue, while excessively low temperatures may affect machining accuracy. Therefore, maintaining an appropriate operating temperature is essential.

Continuously Accumulating Experience and Skills

Finally, the use of stamping dies relies on the accumulation of experience. Over time, novices will gradually become familiar with the characteristics of the die, operating techniques, and solutions to common problems. Continuous learning and summarizing experience can help improve the efficiency of stamping die use and product quality.

Summary

Through the above 10 simple steps, novices can quickly master the skills of using precision stamping dies. In practice, continuously accumulating experience and adjusting operating strategies will help improve the effectiveness of molds and production efficiency. Remembering the maintenance and upkeep of stamping dies, and regularly checking their condition, will help extend their service life and improve production line stability. Precise use of stamping dies is not only key to improving production efficiency but also fundamental to ensuring product quality.