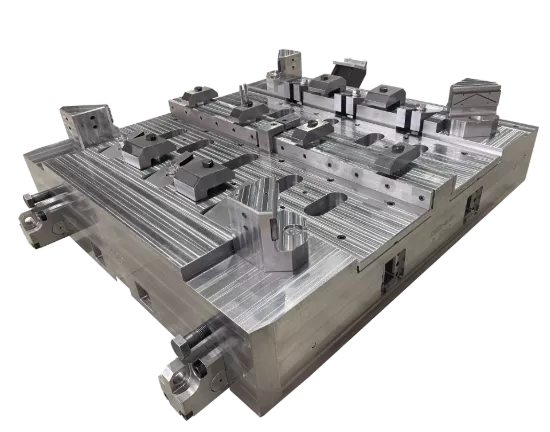

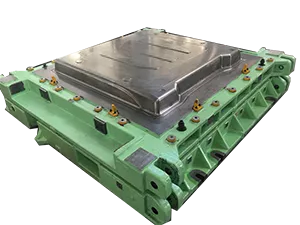

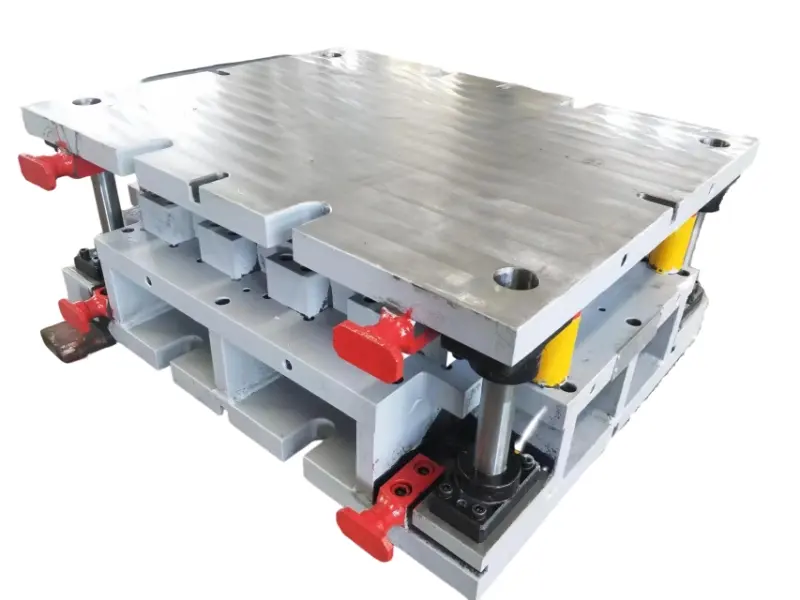

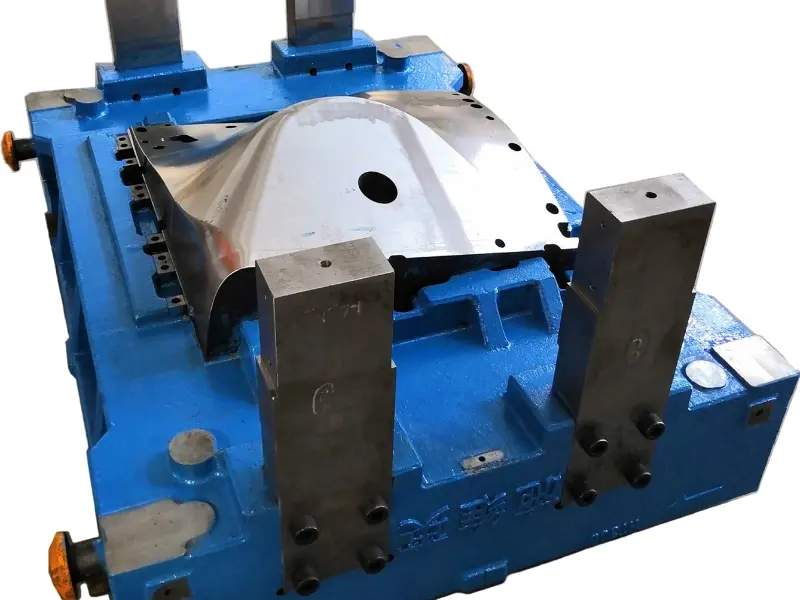

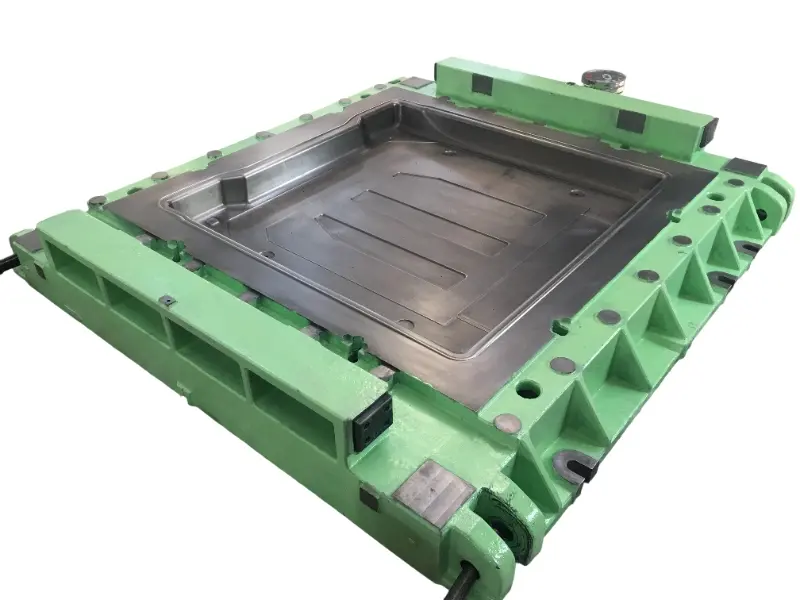

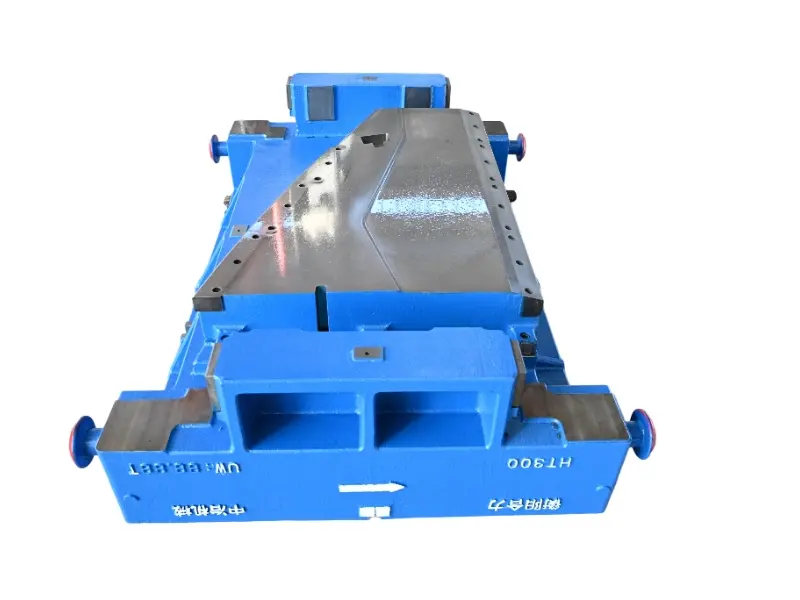

Sheet metal stamping die is the core fixture for achieving precise forming of sheet metal parts. The construction machinery stamping die is a sheet metal stamping die used for construction machinery. Based on advanced mold design and manufacturing technology, it applies external force to metal sheets (such as cold-rolled sheets, stainless steel sheets, aluminum sheets, etc.) through a press machine to complete processes such as punching, bending, stretching, and forming. It is widely used in industries such as automotive, electronics, home appliances, aerospace, etc., providing reliable guarantees for the mass production of various sheet metal products. Based on customer sheet metal drawings (2D/3D), we can analyze product processability (such as minimum fillet radius, stretch ratio), customize mold structures (such as multi slider linkage, oblique wedge mechanism for side punching/side forming), adapt to special materials such as stainless steel and aluminum magnesium alloy, as well as special process requirements such as micro connection and burr free punching, and provide full process services from mold design, manufacturing to trial mold and mass production technical support.

Construction Machinery Stamping Die

steel: HT200,HT300,ZG270-500, ZG310-570, Cr12MoV,SKD11,DC53, etc.

Product Description:

Product Usage

Sheet metal stamping molds cover various industries, mainly including automotive, electronic and electrical, aerospace, medical equipment, etc. The construction machinery stamping die is a sheet metal stamping die used for construction machinery. They are used to produce various stamping products, such as large cover parts such as car doors, engine covers, and roofs, structural components such as outer shells and internal brackets, frames of household appliances such as refrigerators, air conditioners, washing machines, and accessories such as phone, tablet, and laptop shell brackets.

Company Advantages

1. Our company selects modules forged from 10000 ton equipment as the material for our products. The forging pier thickness ratio meets the usage requirements, and the material structure density and performance are higher than general national standards.

2. Our company has a large heat treatment workshop with a maximum weight of 110 tons per heat treatment unit. We can strictly control the hardness of the heat treatment to ensure the performance of the products after heat treatment.

3. Our company has over 20 years of design and production experience, with CNC machining equipment up to 18 meters in length and a maximum CNC machining unit weight of 300 tons.

4. Our company is equipped with large hydraulic mold clamping equipment and three coordinate detection equipment, which can assemble and debug large mold bases. The hydraulic equipment includes 3600T, 2000T, 1900T, 1200T, etc.

5. Our company also has the ability to repair forged mold frames and can weld and repair worn mold frames.