Radial forging die, also known as radial forging die, is a professional tool designed specifically for radial forging machines to achieve precision forming of metal billets through multi-directional radial synchronous extrusion. Its core advantage lies in "multi-directional force, high precision, and suitability for forming long axis parts". It is a key equipment for the manufacturing of high-end long axis forgings (such as wind turbine spindles and aircraft engine shafts).

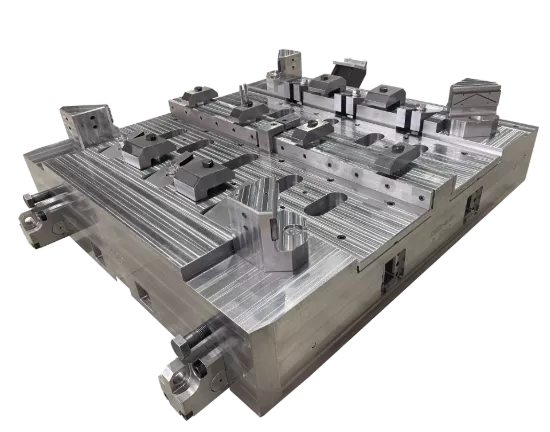

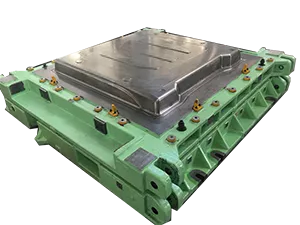

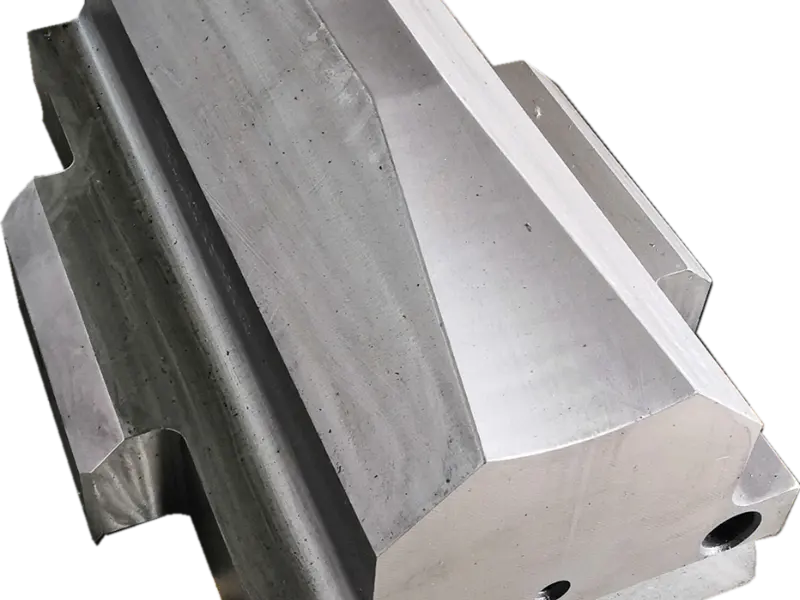

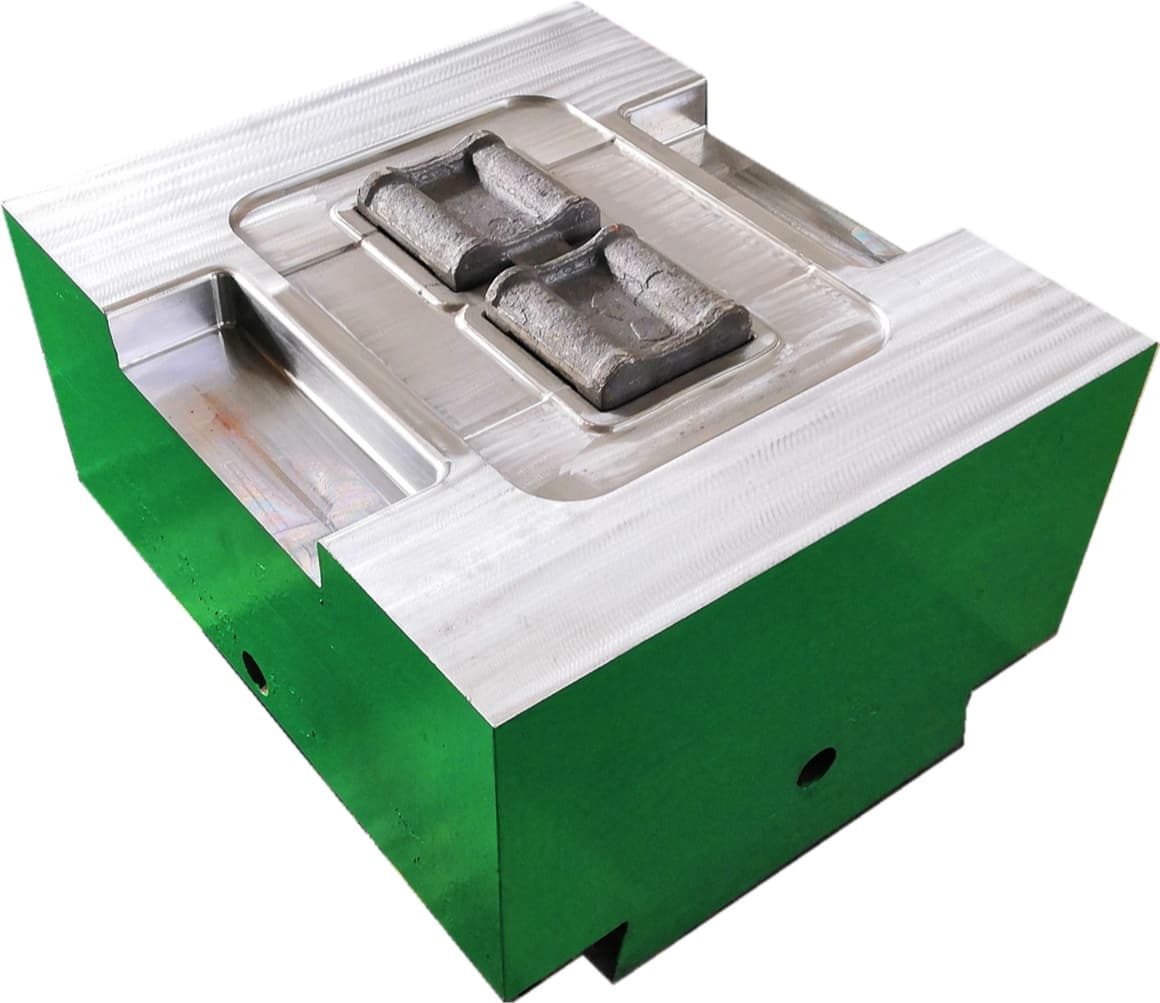

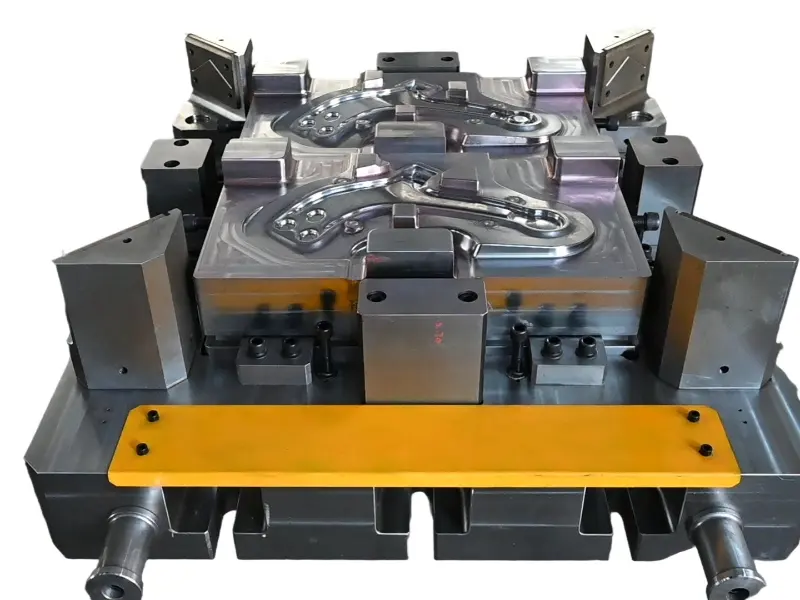

From a structural perspective, it adopts a "multi-mode petal symmetrical distribution" design, usually consisting of 2-4 (commonly 4) mold petals, evenly arranged around the central axis of the forging. Each mold petal is equipped with an independent guide mechanism and drive connection structure, which can achieve synchronous radial feed or independent fine adjustment under the control of the forging machine. The cavity is designed in sections according to the shape of the long axis parts (such as stepped shafts and variable diameter shafts), and reasonable forging allowance and metal flow space are reserved to ensure that the metal billet deforms uniformly along the axial and radial directions under multi-directional extrusion, avoiding local stress concentration. The forging die of a fast forging machine, also known as a fast forging die, is a tool designed specifically for fast forging machines to achieve free forging or die forging of metal billets through rapid reciprocating hammering. Its core advantages lie in "high forging efficiency, adaptability to large-sized billets, and strong universality". It is the core equipment for manufacturing large free forgings (such as large gear blanks and pressure vessel heads).

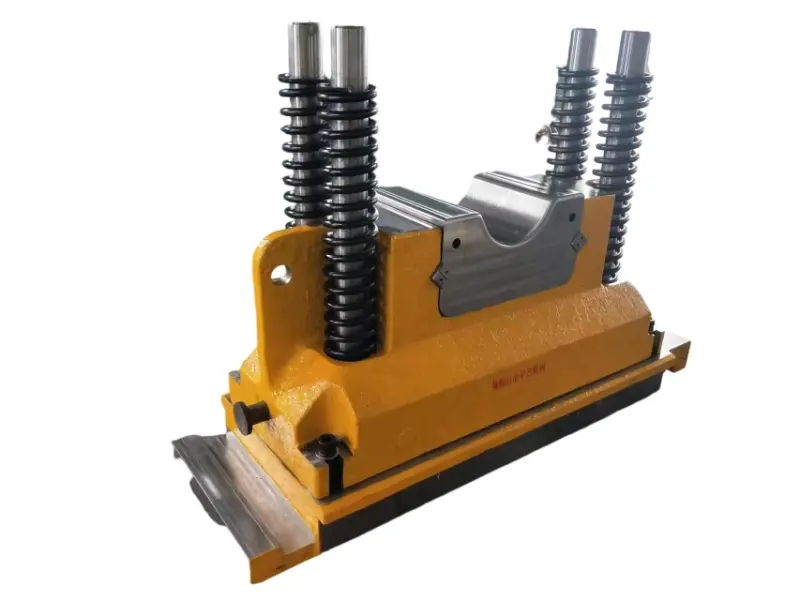

In terms of structural design, forging dies for fast forging machines often adopt a "split or integral single-mode surface" structure. Common types include flat anvil dies, V-shaped anvil dies, upsetting dies, forming dies, etc. Flat anvil dies and V-shaped anvil dies are mainly used for free forging, and basic forging processes such as elongation, upsetting, and punching of metal billets are achieved through simple flat or V-shaped structures; The forming mold has a specific cavity, which is used to achieve preliminary forming of forgings. The mold is equipped with a high-strength connecting handle, which can quickly connect with the hammer and anvil of the fast forging machine, making it easy to quickly replace the mold according to the forging process and improve production efficiency.

Die for Radial Forging Machine and Fast Forging Press

steel:1.2714 / 1.2365 / H13 / 5CrNiMo / 5CrNiMoV / 5CrMnMo / 40CrNiMoA, etc.

Product Description:

Product Usage

The forging die of the radial forging machine, with the characteristics of “multi-directional extrusion and high-precision adaptation to long axis parts”, is mainly used in the manufacturing of long axis and tubular precision forgings. The specific scenarios are as follows:

Batch production of universal free forgings

For small and medium-sized general forgings (such as flange plates and bearing seat blanks), the forging die of the fast forging machine can achieve continuous production of multiple processes such as drawing, upsetting, punching, etc. by quickly replacing different types of anvil dies. Compared with traditional free forging, the production efficiency is increased by 30% -50%, while reducing manual operation intensity, meeting the batch demand for general forgings in the field of mechanical manufacturing.

Manufacturing of long shaft forgings for wind power equipment

In the field of wind power, it is used to produce core components such as wind turbine shafts and generator shafts. Through multi-directional extrusion of the forging die by a radial forging machine, the metal grains inside the forging can be refined, the microstructure dense, the mechanical properties uniform, and internal porosity defects can be avoided.

Manufacturing of aerospace and ship shaft forgings

In the aerospace field, it is used to produce precision shafts such as high-pressure rotor shafts and turbine shafts for aircraft engines. These shafts have small diameters (usually 50-200mm) and high precision requirements, and need to withstand high-speed rotating loads in high temperature (600-800 ℃) environments. The mold can achieve complex structural forming such as stepped diameter change and thin neck by accurately controlling the feed rate of the mold disc; In the field of ships, it is used to produce ship propulsion shafts, crankshaft main journals, etc., suitable for power systems of large ocean going cargo ships and special ships, ensuring the service life of shaft components under seawater corrosion and heavy load conditions.

Manufacturing of long shaft components for petroleum drilling and engineering machinery

In the field of petroleum drilling and production, it is used to produce drill pipe joints, pumping unit spindles, etc. These parts need to withstand underground high pressure, corrosive environment, and high-frequency vibration. By forging molds with a radial forging machine, the fatigue strength and wear resistance of the parts can be improved, ensuring the continuous operation of petroleum drilling and production equipment; In the field of construction machinery, it is used to produce telescopic arm shafts and slewing support shafts for excavators and cranes, so that the shafts are not easily deformed under heavy load conditions, improving the safety and reliability of construction machinery operations. The forging dies of fast forging machines are mainly used in the manufacturing of large free forgings and general-purpose forgings due to their characteristics of “efficient hammering and adaptability to large-sized billets”. The specific scenarios are as follows:

Manufacturing of large forgings for heavy machinery

In the field of heavy machinery, it is used to produce large gear blanks, rolling mill memorial archway, crusher spindle and other forgings. The diameter of large gear blanks can reach 2-5 meters and weigh over 10 tons. Through the rapid upsetting and elongation of the forging die by a fast forging machine, uniform deformation of the blank can be achieved, and defects such as internal looseness and porosity can be removed, providing high-quality blanks for subsequent machining; As the core load-bearing component of rolling equipment, the mill memorial archway weighs 50-200 tons. Through repeated reciprocating hammering, the die can make the forging compact and meet the load-bearing demand of the mill under the rolling force of 10000 tons.

Manufacturing of pressure vessels and nuclear power equipment forgings

In the field of pressure vessels, it is used to produce pressure vessel head and cylinder forgings. These forgings need to withstand high pressure (10-100MPa) and corrosive media. Through the upsetting and forming of the forging die by a fast forging machine, the wall thickness of the forgings can be made uniform, avoiding the problem of wall thickness deviation exceeding the tolerance.

Manufacturing of metallurgical and mining equipment forgings

In the field of metallurgy, it is used to produce forgings such as steelmaking converter ear shafts and continuous casting machine roller sleeves.