Five Key Factors to Consider When Purchasing Forging Dies

Release time: 2025-10-10

Table of Contents

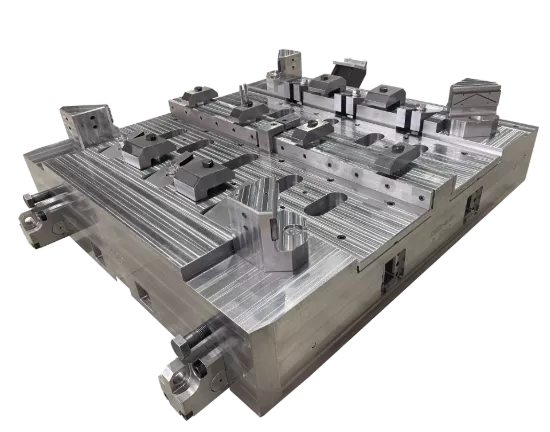

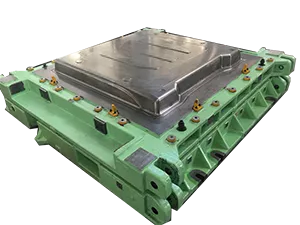

Forging dies are crucial tools in industrial production, directly impacting product quality and production efficiency. Whether in the aerospace, automotive, or heavy machinery industries, selecting suitable forging dies plays a vital role in improving production capacity and reducing costs. However, with numerous different types of forging dies available on the market, choosing high-precision forging dies has become a significant challenge for many manufacturers. This article from Zhongye will introduce five key factors to consider when purchasing forging dies.

Die Material Selection

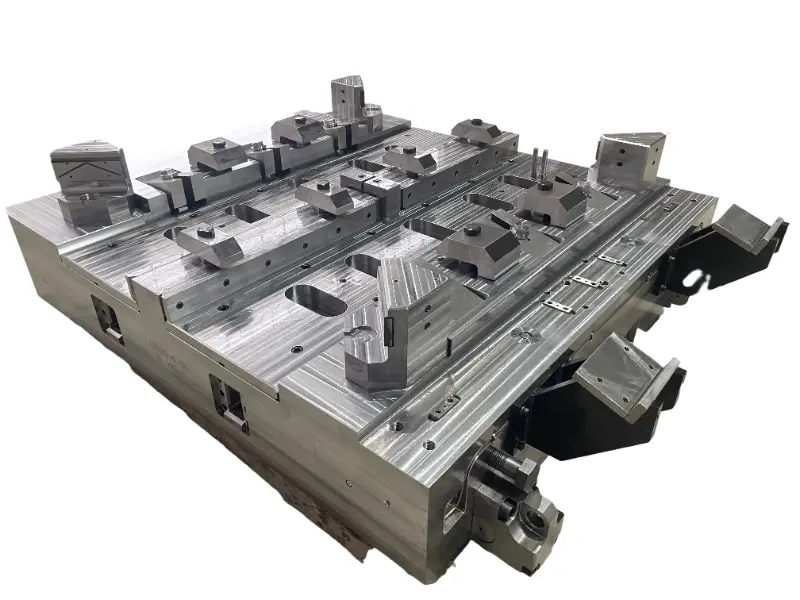

The material of a forging die directly affects its performance and service life. Generally, the choice of die material depends on the type of product being produced and the production conditions. Common forging die materials include high-speed steel, tool steel, and alloy steel, each with its own characteristics. For example, high-speed steel dies have excellent wear resistance and thermal crack resistance, making them suitable for mass production of high-precision parts. When purchasing, the appropriate material should be selected based on the working temperature, pressure, and frequency of use of the die.

Die Design Rationality

The design of a forging die is one of the key factors determining its effectiveness and efficiency. The structural design of a mold should consider factors such as the production process, the dimensional accuracy of the product, and the mold’s lifespan. A well-designed mold can not only improve production efficiency but also reduce production costs. For example, a well-designed cooling system can help the mold cool down faster, shorten the production cycle, and extend the mold’s lifespan.

Furthermore, the dimensional tolerances and surface roughness of the mold also require special attention. These factors directly affect the quality and appearance of the product; therefore, when selecting forging dies, it is recommended to choose those with excellent designs that meet industry standards.

Wear Resistance and Heat Resistance

Forging dies are used in high-temperature and high-pressure environments, and prolonged high-intensity operation can easily lead to wear and thermal cracking. Therefore, selecting a forging die with good wear resistance and heat resistance is crucial. A wear resistance forging die can reduce production interruptions caused by wear, thereby improving production continuity. A die with strong heat resistance can maintain stable performance in high-temperature environments, extending the mold’s lifespan.

When purchasing, it is recommended to prioritize dies that have undergone heat treatment, as these dies typically have stronger high-temperature resistance and impact resistance.

Mold Machining Accuracy

The machining accuracy of a mold directly affects the quality of the produced product. Forging molds typically require high precision, so careful consideration must be given to their machining accuracy when selecting one. High-precision molds not only produce more refined parts but also prevent product quality issues caused by mold errors. When choosing a mold, check the mold manufacturer’s technical qualifications and production equipment to ensure they possess high machining accuracy.

Furthermore, for molds requiring a high surface finish, attention should be paid to surface treatments such as electroplating and spraying to ensure a smooth surface and reduce friction and wear.

Mold Cost and Cost-Effectiveness

Finally, the cost and cost-effectiveness of forging molds must be considered when purchasing them. While high-quality forging molds are often more expensive, their long-term performance and reduced maintenance costs make them more cost-effective. When selecting, weigh the cost and performance of the mold based on production scale and needs. For large-scale production, choosing high-quality, high-precision forging molds will save costs; while for small-batch production, forging molds with a higher cost-effectiveness can be chosen.

In addition, don’t forget to consider after-sales service. A forging die supplier with good after-sales service can provide timely maintenance and technical support to ensure smooth production.

Summary

Selecting the right forging die is a crucial step in improving production efficiency and reducing production costs. During the selection process, paying attention to factors such as die material selection, design rationality, wear resistance, machining accuracy, and cost-effectiveness will help you choose the die best suited to your needs. Through reasonable selection, you can improve production efficiency and reduce unnecessary losses while ensuring product quality.