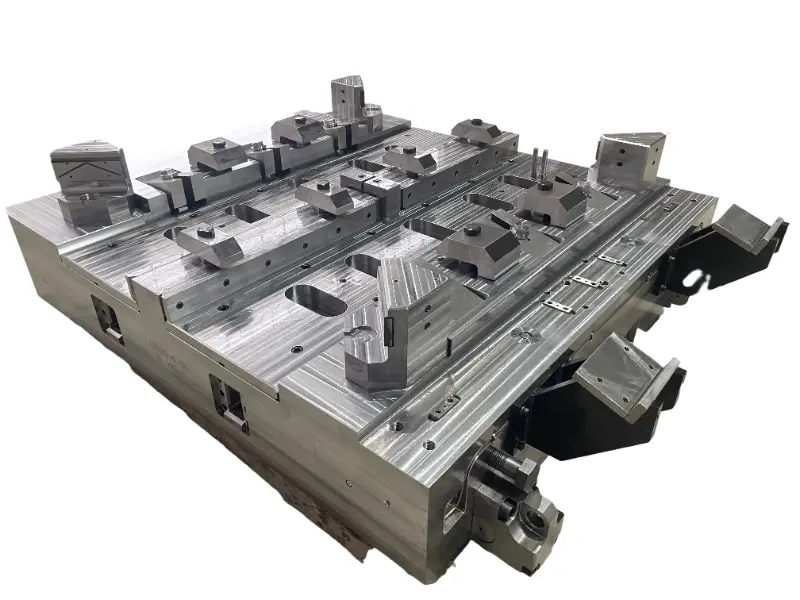

Used on large forging equipment, the forging equipment used is below 4000T, and the forging equipment type is hot forging press. The Hydraulic Locking Forging Die Set, as the core connecting component between forging equipment and molds, is a key basic component to ensure stable and efficient forging processes. It achieves automatic mold replacement, rapid clamping, precise positioning, reduces personnel installation time, and improves production efficiency by configuring a small hydraulic system, as well as hydraulic cylinders and control systems. At present, it is mainly used in the automation production process to cooperate with six axis robots to complete the production of aluminum forgings.

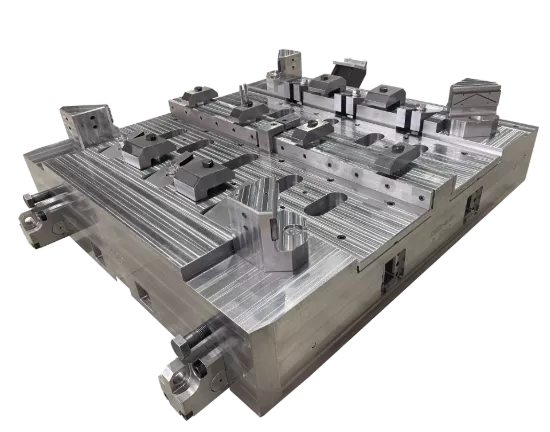

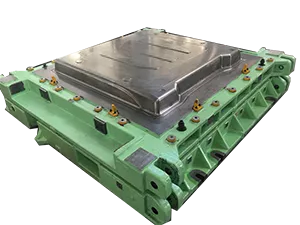

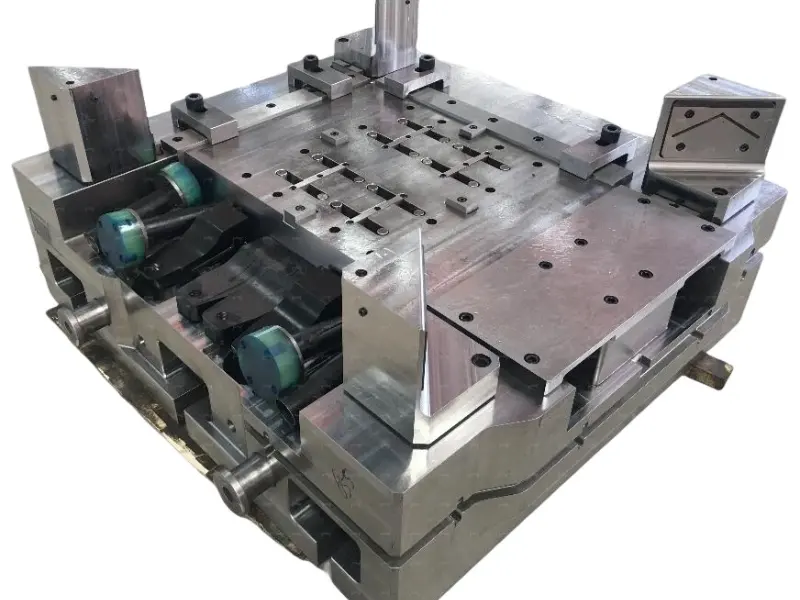

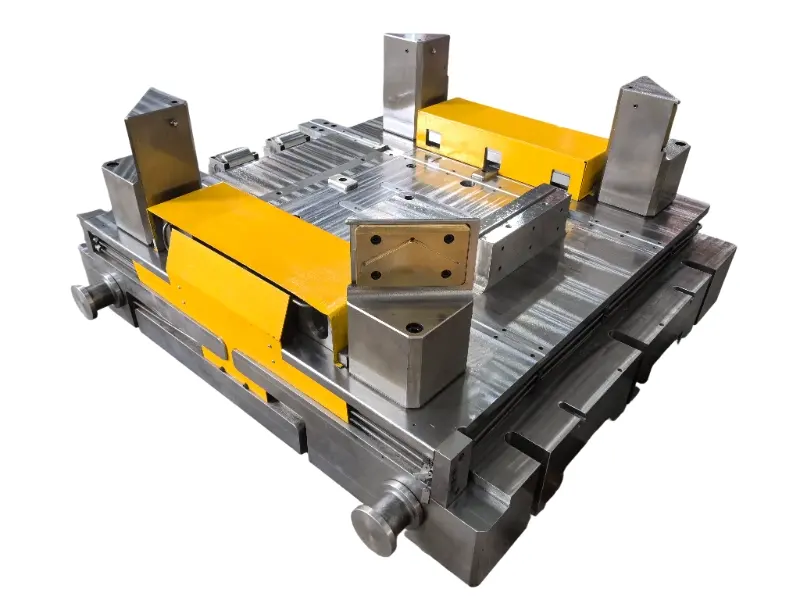

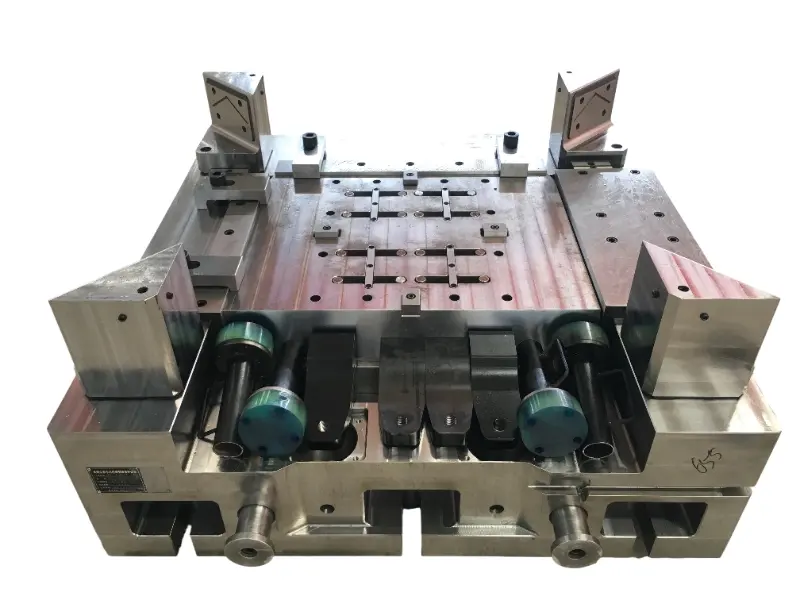

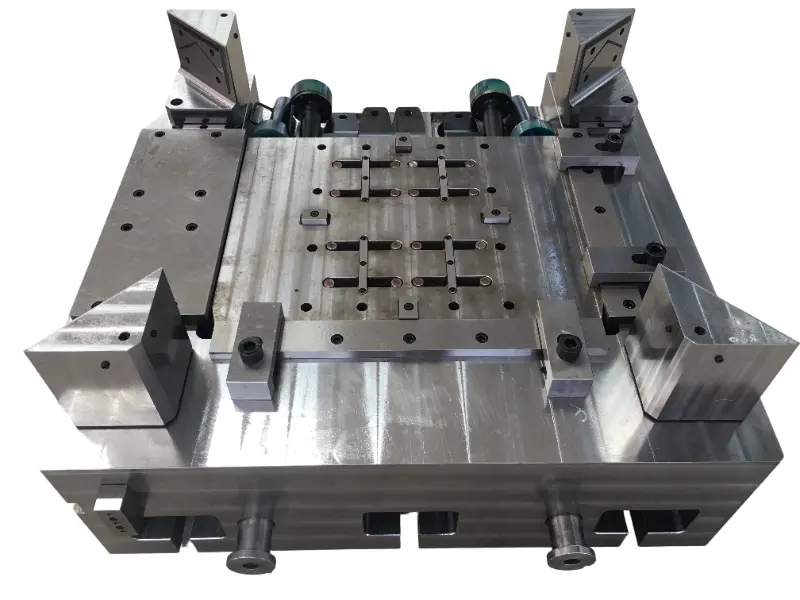

Hydraulic Locking Forging Mold Frame

steel: 1.2714 / 56NiCrMoV7 / 40CrNiMoA /5CrNiMo, etc.

Product Description:

Product Usage

In forging production, the Hydraulic Locking Forging Mold Frame can achieve automatic clamping and releasing of the mold through a configured control system in the operating system, without the need for manual disassembly and assembly of the mold, reducing mold changing time and personnel workload, and improving mold changing speed and production efficiency. At the same time, the forging die seat provides a rigid installation reference for the upper and lower molds, ensuring that the molds are not offset under high pressure and guaranteeing the dimensional consistency of complex forgings (such as automotive crankshafts and aircraft engine blades); During the operation of hot forging press, its excellent heat resistance can reduce deformation caused by repeated high-temperature impacts and extend the mold replacement cycle; It can evenly distribute pressure to the working surface of the mold, avoiding mold cracking caused by local stress concentration. In addition, on the multi-directional forging hydraulic press, the customized die seat can adapt to multi-directional force molds, meeting the complex forming requirements of irregular forgings.