Key Techniques for Success in Forging Mold Frame in Metalworking

Release time: 2025-12-04

Table of Contents

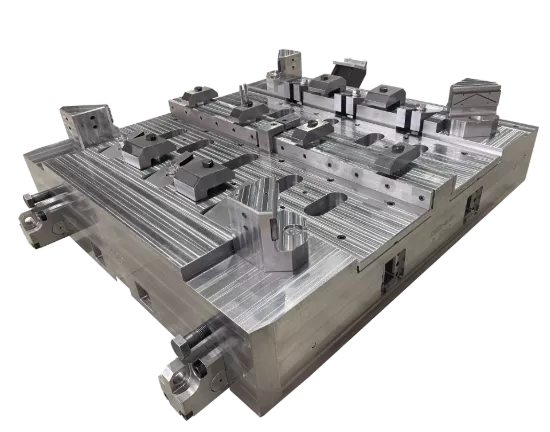

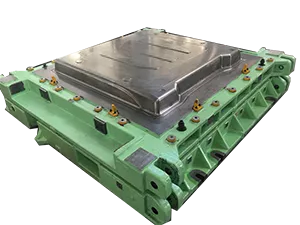

In the metalworking industry, the forging mold frame plays a crucial role, especially in heavy forging and complex part production processes. The quality and design of the forging mold frame directly impact production efficiency and the final product quality. For professionals in the metalworking field, mastering the key techniques for successful forging mold frames is essential for ensuring smooth production and enhancing product quality.

Choosing the Right Mold Frame Material

The choice of material for the forging mold frame is critical to its performance and durability. Common materials used for forging mold frames include alloy steel, tool steel, and high-strength steel. Selecting the appropriate material can significantly improve the mold frame’s wear resistance, compressive strength, and service life. Therefore, it is important to consider the temperature and pressure requirements of the forging process when selecting the mold frame material.

Precise Mold Frame Design

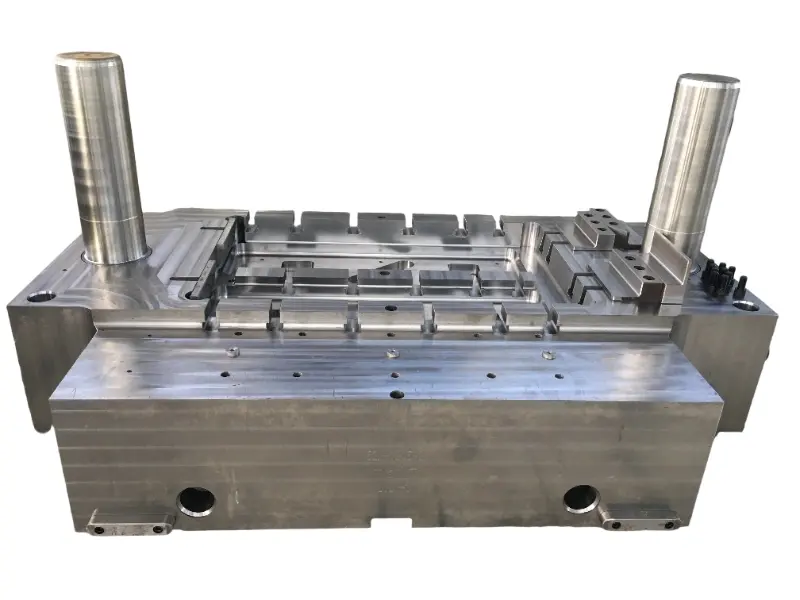

The design of the forging mold frame must take into account the shape, size, and processing requirements of the workpiece. A precise design not only improves production efficiency but also ensures the quality of the finished product. During the design process, special attention should be paid to the strength, rigidity, and heat treatment properties of the mold frame. A reasonable design can prevent deformation and damage of the mold, reducing the number of defective products during production.

Choosing a Reliable Forging Mold Frame Supplier

Choosing a reliable forging mold frame supplier is key to ensuring product quality and delivery timelines. A good supplier can provide high-quality mold frame materials and precise manufacturing processes, ensuring the stability and efficiency of the mold frame during long-term use. When selecting a supplier, it is useful to review their past client evaluations, case studies, and technical support capabilities to make an informed decision.

Appropriate Heat Treatment for Mold Frames

The heat treatment process of the mold frame plays a decisive role in its performance. Forging mold frames usually require strict heat treatment to enhance their hardness, strength, and wear resistance. By applying appropriate annealing, quenching, and tempering processes, the service life of the mold frame can be extended, and deformation or damage under high temperature or pressure conditions can be prevented.

Regular Maintenance and Inspection of Mold Frames

To ensure the long-term stability of the forging mold frame, regular inspection and maintenance are essential. Periodically checking for wear, surface cracks, and deformation can help identify potential problems and take corrective measures. Maintaining the lubrication system of the mold frame is also an effective way to prolong its service life. Good maintenance practices can significantly reduce the failure rate of mold frames and improve production continuity.

Adopting Advanced Processing Technologies

With the continuous advancement of technology, more advanced processing technologies are being applied in the manufacturing of forging mold frames. For example, the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies can help improve the precision of mold frame designs and production efficiency. Additionally, modern CNC equipment and laser cutting technologies also enhance the processing accuracy of mold frames, making them more suitable for complex processing needs.

Optimizing Forging Process Parameters

The parameters of the forging process, such as temperature, pressure, and speed, directly affect the performance of the forging mold frame. In practical production, optimizing these parameters can not only improve the quality of the forged parts but also extend the life of the mold frame. Reasonable process parameters can reduce mold wear and prevent excessive thermal stress from damaging the mold frame.

Considering the Adaptability of Mold Frames

The adaptability of the forging mold frame is extremely important, especially when processing different forging materials or applying different forging processes. A high-quality forging mold frame should have good adaptability, capable of withstanding the challenges posed by material and process variations. Therefore, when designing the mold frame, its versatility and adjustability should be fully considered.

Controlling Temperature During the Forging Process

Temperature is a crucial factor influencing the service life of the mold frame during forging. Excessively high temperatures can lead to fatigue of the mold frame material, while excessively low temperatures may increase the brittleness of the mold. Therefore, maintaining an appropriate temperature range, particularly during heavy forging, can effectively prevent mold frame damage and improve processing quality.

Continuous Innovation and Technological Updates

As metalworking technology continues to evolve, the design and manufacturing processes of forging mold frames are also constantly innovating. Keeping up with the latest technological trends and exploring new materials and design ideas can continuously improve the performance and adaptability of the mold frame. This not only boosts production efficiency but also provides a competitive edge in the market.

Conclusion

In metalworking, the successful application of the forging mold frame is key to improving production efficiency and product quality. By choosing the right materials, ensuring precise design, performing regular maintenance, and adopting advanced technologies, mold frames can operate efficiently under high-strength, high-temperature, and high-pressure conditions. Choosing a reliable forging mold frame supplier and optimizing the forging process parameters further guarantees the long-term stability and efficiency of the mold frame. Mastering these key techniques will help improve the overall performance of the production line and reduce manufacturing costs.