Maintenance and Care Techniques for Forging Dies to Extend Service Life

Release time: 2025-10-31

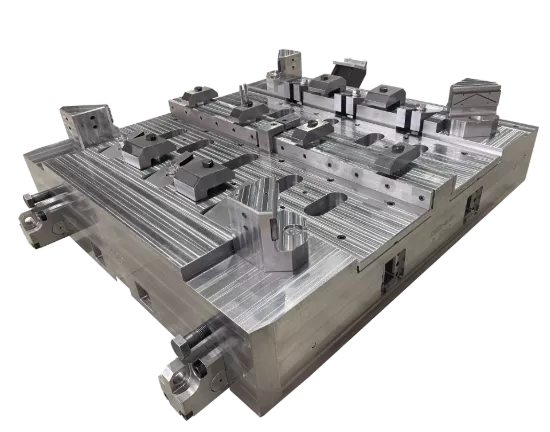

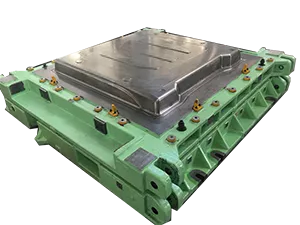

Forging dies are essential tools in various production processes, directly impacting production efficiency and product quality. However, due to their operation under high temperature and pressure, forging dies are prone to wear and damage over time. Therefore, proper maintenance and care can not only extend their service life but also improve production efficiency and reduce costs. Zhongye will introduce some effective maintenance techniques to help you better manage your forging dies.

Regularly Clean the Die Surface

Forging dies easily accumulate metal shavings, rust, and other impurities during operation. If not cleaned promptly, these impurities can damage the die surface and even affect product precision. Therefore, regularly cleaning the forging die surface is the first step in maintenance. Use a soft brush, cleaning cloth, or compressed air to remove residual debris and prevent friction damage from metal particles.

In addition, during cleaning, check for blockages in the die’s cooling channels to ensure effective cooling and prevent damage from overheating.

Proper Die Storage

The storage environment of the die also significantly affects its lifespan. When storing forging dies, choose a dry, well-ventilated place to avoid humid environments, as moisture can easily cause rust. To reduce corrosion, it is recommended to treat the die surface with rust-preventive measures, such as applying rust-preventive oil or using rust-proof packaging materials.

Furthermore, avoid collisions with hard objects during storage to prevent damage or deformation of the die surface. Proper die storage can effectively extend the die’s service life.

Regularly check the die’s wear condition

Even wear-resistant forging dies will experience varying degrees of wear during long-term use, especially under high-frequency use. Therefore, regular checks of the die’s wear condition are necessary. During inspection, focus on important parts such as the working surfaces, guide surfaces, and cooling channels. If severe wear is found, repair or replace die parts to ensure normal die operation.

In addition to checking for wear, regularly check the die’s dimensional accuracy to ensure it meets design requirements. If deviations in accuracy occur, adjust or repair them promptly to avoid affecting production quality.

Use a suitable lubricant

Lubricants play a crucial role in the maintenance of forging dies. Using a suitable lubricant can reduce friction, decrease wear, and extend the service life of the die. When selecting a lubricant, the appropriate type should be chosen based on the die material, working environment, and production process. Common high-temperature lubricating oils and high-performance greases are good choices, as they effectively reduce the coefficient of friction and minimize thermal damage.

Furthermore, regularly checking the quality of the lubricating oil is necessary to ensure it is not contaminated and maintains good lubrication performance.

Regular Heat Treatment

The durability and performance of forging dies are often closely related to their heat treatment process. Proper heat treatment can improve the hardness and wear resistance of forging dies, thereby extending their service life. During the use of the die, regular heat treatments, such as annealing, quenching, or tempering, should be performed as needed to restore the die’s performance.

During heat treatment, special attention must be paid to temperature control to avoid thermal cracking or deformation of the die due to excessively high or low temperatures.

Summary

The maintenance and upkeep of forging dies are key to improving production efficiency and extending the service life of forging dies. Regularly cleaning the die surface, proper storage, checking for wear, using suitable lubricants, and performing necessary heat treatments can significantly improve the performance and production stability of forging dies. Following these maintenance techniques not only reduces repair costs but also ensures consistent product quality.

Choosing the right forging die and performing scientific maintenance is fundamental to ensuring smooth production. We hope the maintenance recommendations in this article will provide you with valuable guidance to help you better manage and maintain your die equipment. If you have any further questions about forging dies, please feel free to contact us. As a forging die manufacturer, we will provide you with the most professional die solutions.