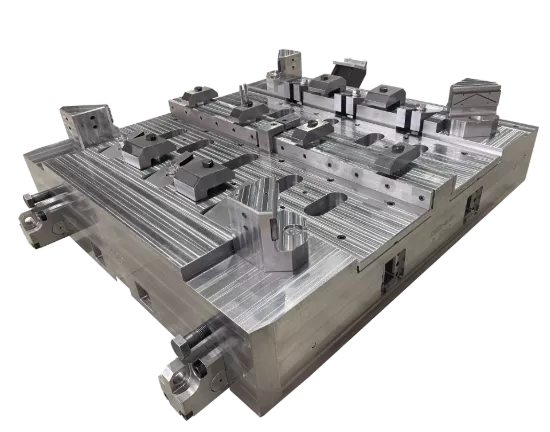

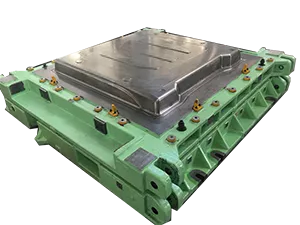

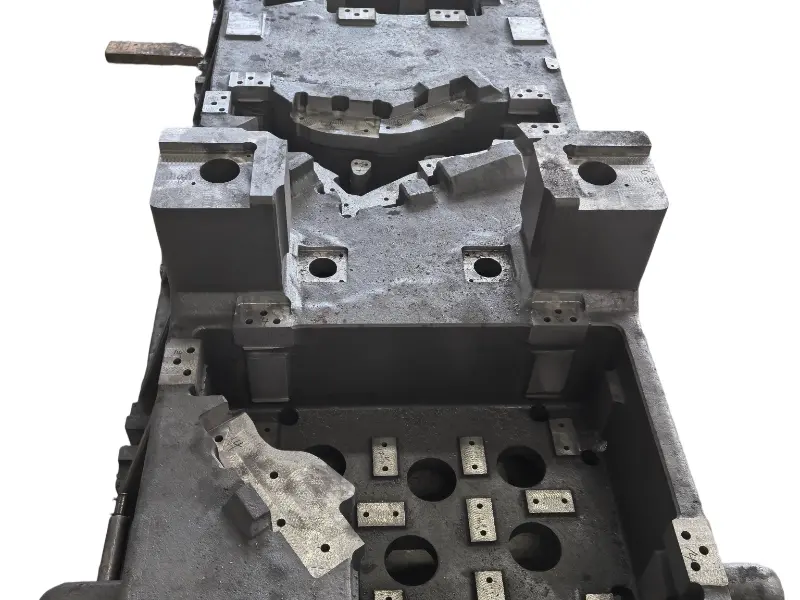

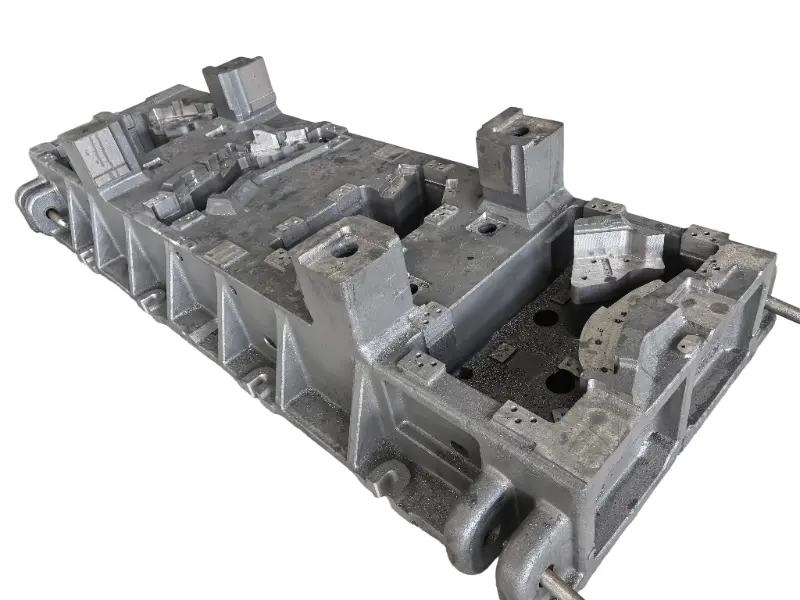

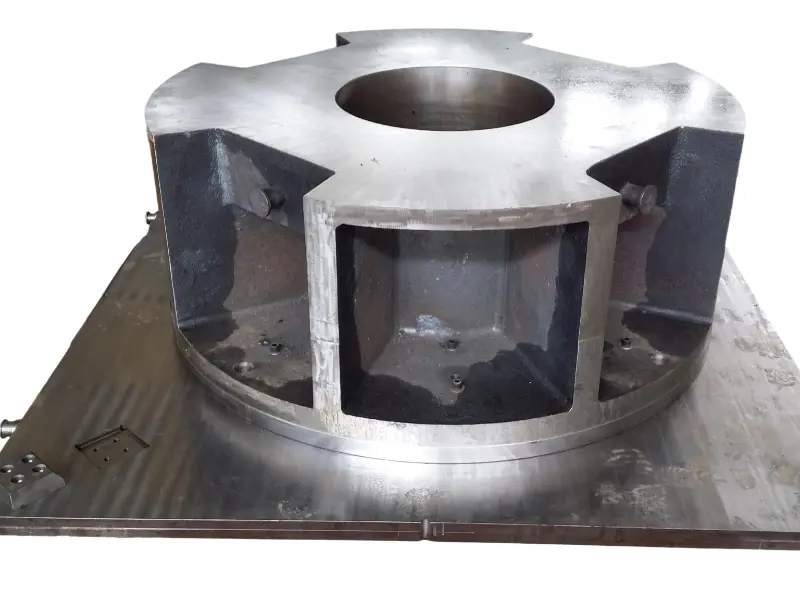

The processing of parts includes the processing of cast steel parts, cast iron parts, welded parts, and forged parts. Non standard parts are CNC machined, assembled, and debugged to meet the relevant technical requirements of mechanical equipment and tooling accessories.

parts processing

Steel: HT200, HT300, ZG270-500, ZG310-570, SKD11, 45#, Q355, etc.

Product Description:

Product Usage

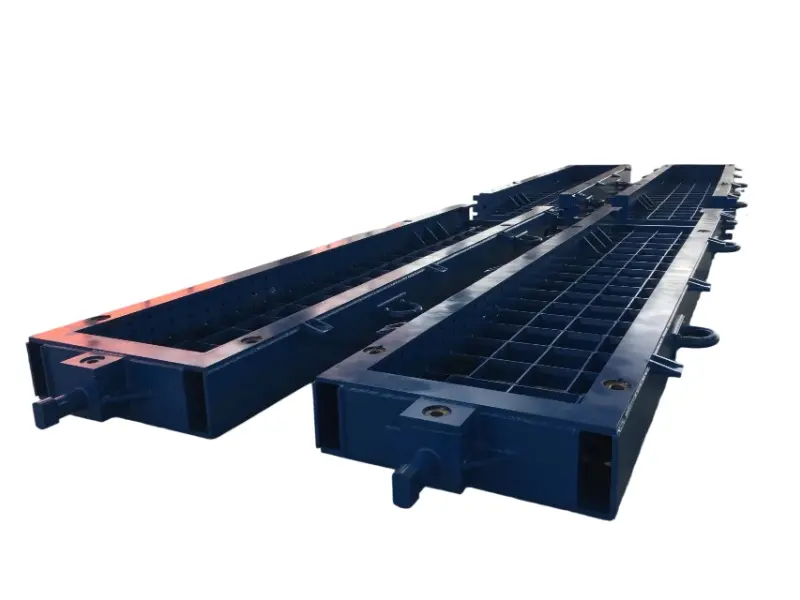

The use of non-standard components covers various products, such as mechanical equipment, mechanical parts, equipment bed bodies, welding parts, work platforms, various fixtures, oil cylinder castings, marine accessories, wear-resistant castings, machined parts, etc.

Company Advantages

1. Our company selects modules forged from 10000 ton equipment as the material for our products. The forging pier thickness ratio meets the usage requirements, and the material structure density and performance are higher than general national standards.

2. Our company has a large heat treatment workshop with a maximum weight of 110 tons per heat treatment unit. We can strictly control the hardness of the heat treatment to ensure the performance of the products after heat treatment.

3. Our company has over 20 years of design and production experience, with CNC machining equipment up to 18 meters in length and a maximum CNC machining unit weight of 300 tons.

4. Our company is equipped with large hydraulic mold clamping equipment and three coordinate detection equipment, which can assemble and debug large mold bases. The hydraulic equipment includes 3600T, 2000T, 1900T, 1200T, etc.

5. Our company also has the ability to repair forged mold frames and can weld and repair worn mold frames.