5 важнейших факторов, которые следует учитывать при разработке и изготовлении на заказ основания для крупномасштабной ковочной формы

Дата выпуска: 26.12.2025

Оглавление

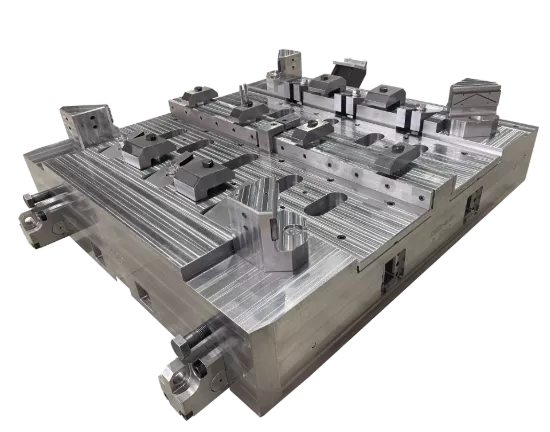

В мире тяжелой промышленности, где ставки высоки, качество конечного продукта напрямую зависит от фундамента, на котором он построен. Когда речь идет о производстве массивных промышленных компонентов, основание для крупномасштабной ковочной формы служит именно таким фундаментом.

Изготовление пресс-формы на заказ для крупномасштабных операций — это значительные инвестиции, требующие баланса между точностью проектирования и исключительной прочностью. Независимо от того, производите ли вы компоненты для аэрокосмической отрасли или автомобильные шасси, вот пять важнейших факторов, которые гарантируют, что ваша изготовленная на заказ пресс-форма для ковки будет соответствовать самым высоким отраслевым стандартам.

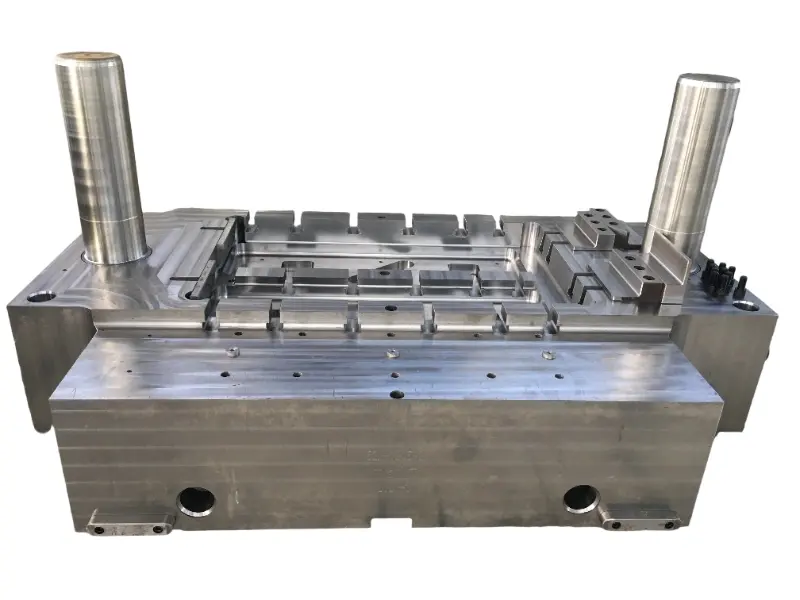

Выбор материалов и металлургическая целостность

Суровые условия кузнечного дела, характеризующиеся экстремальными температурами и циклическим давлением, требуют использования материалов высшего качества. основание пресс-формы для прецизионной ковки, Стандартной стали зачастую недостаточно.

Долговечность: Для обеспечения устойчивости к термической усталости и деформации необходимы высококачественные инструментальные стали или специальные сплавы.

Конкретные области применения: Если ваш проект связан с легкими металлами, выбор алюминиевой ковочной формы требует учета особых требований к теплопроводности для обеспечения равномерного охлаждения и структурной целостности.

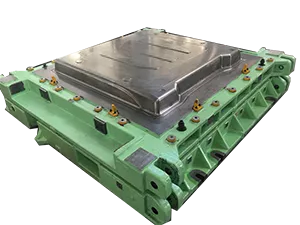

Жесткость конструкции и распределение нагрузки

Крупномасштабная ковка требует огромных усилий. Неправильно спроектированное основание ковочной формы может деформироваться или треснуть под давлением, что приводит к дорогостоящим простоям и браку деталей.

Анализ методом конечных элементов: Убедитесь, что ваш производитель использует метод конечных элементов (МКЭ) для моделирования распределения напряжений.

Стабильность: Основание должно быть спроектировано таким образом, чтобы поглощать удары и сохранять соосность даже после тысяч циклов.

Точная механическая обработка и допуски

В крупномасштабном производстве “большой” не означает “рыхлый”. Даже отклонение в несколько микрометров может привести к образованию заусенцев, несовпадению линий разъема или структурным недостаткам кованой детали.

Высокоточные станки с ЧПУ: Для обеспечения индивидуальной настройки необходимо использовать передовые технологии обработки на станках с ЧПУ. основание для ковочной формы на заказ Идеально подходит к ковочному прессу и вставкам для штампов.

Качество обработки поверхности: Гладкая и точная обработка поверхности снижает трение и продлевает срок службы как основания пресс-формы, так и штампа.

Системы охлаждения и терморегулирования

Постоянный контроль температуры — залог высококачественной ковки. При разработке формы для литья крайне важно учитывать наличие внутренних каналов охлаждения.

Тепловой баланс: Эффективное охлаждение предотвращает перегрев формы, что поддерживает твердость стали и обеспечивает стабильность размеров основания ковочной формы на протяжении всего производственного цикла.

Совместимость и простота обслуживания

При проектировании основания крупномасштабной ковочной формы следует учитывать потребности оператора.

Взаимозаменяемость: Можно ли быстро заменить вставки?

Стандартизация: Хотя базовая конструкция изготавливается на заказ, использование стандартизированных компонентов для изнашиваемых деталей (таких как втулки и направляющие штифты) может значительно снизить долгосрочные затраты на техническое обслуживание и сроки поставки.

Сводная таблица: Основные характеристики нестандартных оснований

| Фактор | Важность | Рекомендуемый подход |

| Материал | Экстремальный | Высоколегированная инструментальная сталь (например, H13 или 4140) |

| Допуск | Высокий | Прецизионная шлифовка и фрезерование на станках с ЧПУ. |

| Охлаждение | Существенный | Интегрированные контуры водяного или масляного охлаждения |

| Настройка | Критический | Разработан с учетом конкретного тоннажа и хода пресса. |

Заключение

Инвестиции в высококачественную, изготовленную на заказ основу для ковочной формы — это стратегический шаг, который окупается снижением брака, сокращением циклов и увеличением срока службы инструмента. Сосредоточившись на целостности материала, точности и тепловом регулировании, вы обеспечите конкурентоспособность и эффективность вашего крупномасштабного ковочного производства.

Ищете ли вы основание для ковочной формы повышенной прочности Для производства специализированных пресс-форм для точной ковки сотрудничество с опытным производителем — это первый шаг к совершенству в промышленности.