Care & maintenance

Through scientific maintenance to prevent failures, precise repairs to restore performance, and technological upgrades to improve efficiency, we help customers reduce production costs, stabilize production quality, and maximize the value of molds.-

01

Fault Diagnosis & Repair

For common mold problems (such as edge chipping, cavity wear, cracks, and ejector failure), we use non-destructive testing and mechanical property analysis to accurately pinpoint the cause. We also offer professional repair solutions, including edge repair, overlay welding, cavity polishing, and component replacement, to restore the mold's original precision and performance.

-

02

Wear repair & strengthening treatment

Advanced technologies such as laser cladding and high-alloy welding are used to repair severely worn mold working surfaces, improving surface hardness and wear resistance. Surface strengthening treatments (such as carburizing, nitriding, and chrome plating) are performed on vulnerable areas (such as the die bore of forging dies and the cutting edges of stamping dies) to extend their service life.

-

03

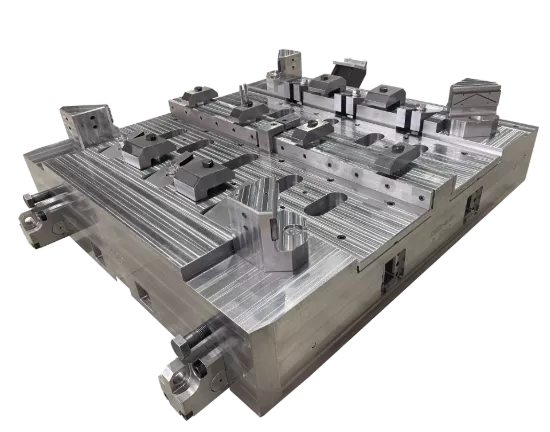

Assembly accuracy restoration

Disassemble and inspect the mold components for proper fit, correcting or replacing loose or deformed parts. During reassembly, strictly control assembly accuracy, including parallelism and perpendicularity, to ensure stable mold operation.

-

04

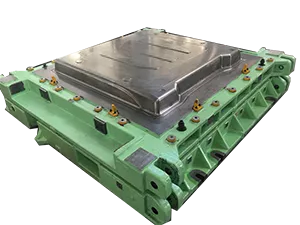

Welding repair of mold frame cracks

Welding repair of cracked mold and die base. Our company has rich experience in repairing molds and die bases. We have our own large-scale welding and heat treatment workshops, which can carry out welding repairs on cracked and worn mold and die bases. Especially for cracked and scrapped mold and die bases, our company has rich experience in welding repairs. Through welding repairs, the service life of molds and die bases is prolonged, creating considerable economic value for the user units.

-

05

Maintenance content

We tailor a personalized maintenance plan based on mold material (e.g., hot-work mold steel, cold-work mold steel), operating conditions (forging temperature, stamping speed, material hardness), and production batch size, clearly defining maintenance priorities, cycles, and methods to reduce customer maintenance costs. We provide daily mold maintenance training to customer operators, covering cleaning procedures, lubrication guidelines, and simple fault diagnosis. This training enhances on-site maintenance capabilities and reduces mold damage caused by human intervention. We conduct lifespan assessments on molds reaching service end or experiencing performance degradation, analyzing wear patterns and failure causes. We also provide technical advice on mold structure optimization and material upgrades, improving mold durability and production efficiency through local modifications.

Technical consulting & services

Professional technology as the foundation, customer demand as the orientation, quality assurance as the core.-

01

Provide mold and mold base design solutions.

-

02

Participate in the design and commissioning of robots used in automated production processes.

-

03

Provide mold and mold base maintenance solutions and technical support.

-

04

Provide mold and mold base repair solutions.

-

05

Provide mold base hydraulic system modifications and technical support.

-

06

Provide comprehensive process flow and technical solutions for stamping parts.

-

07

Participate in the design and optimization of non-standard products.

-

08

Participate in the processing and optimization of mechanical equipment parts.

-

09

Provide welded parts design and welding process solutions.

Precision Forged, Innovation Stamped

Spare Parts Center

Professional technology as the foundation, customer demand as the orientation, quality assurance as the core.-

Spare Parts Center Positioning

-

Core Services

-

Technical Support and Support Services

-

Spare Parts Center Positioning

The Spare Parts Center is positioned as "precise supply, quality assurance, and efficient service" and is committed to providing full-category, high-quality spare parts solutions to industrial enterprises, forging, stamping companies, and equipment companies, becoming an efficient bridge connecting spare parts production and terminal applications.

-

Core Services

1. Standardized Parts Library

This library covers standard general mechanical parts (bolts, nuts, springs, bearings, gears, etc.), specialized equipment parts (such as machine tool spindles, hydraulic components, pneumatic accessories, etc.), and customized parts (precision aerospace parts, automotive core components, and specialized parts for mechanical equipment). We have established a comprehensive parts inventory network covering a wide range of materials, including metal, plastic, and ceramic, and sizes from micro to large.

2. Full-Process Customization Service

To meet specific customer needs (such as non-standard sizes, special working conditions, and batch customization), we collaborate with high-quality upstream fabrication manufacturers and design teams to provide a full-process customization service, from drawing review, material selection, process optimization, to production delivery, ensuring a precise match between customized parts and customer equipment. -

Technical Support and Support Services

1. Parts Selection Consultation

Relying on our experienced technical team, we provide customers with guidance on parts selection. We recommend compatible models, materials, and brands based on equipment operating conditions (such as temperature, pressure, and speed), reducing the risk of selection errors.

2. Installation and Application Guidance

For complex components (such as precision bearings, hydraulic cylinders, and hydraulic systems), we provide on-site installation and commissioning support, technical parameter calibration, and maintenance training to ensure optimal performance.

3. After-Sales Support System

A 24/7 after-sales response mechanism has been established, providing free returns and exchanges for parts with quality issues and remote assistance within 48 hours for technical issues that arise during use.