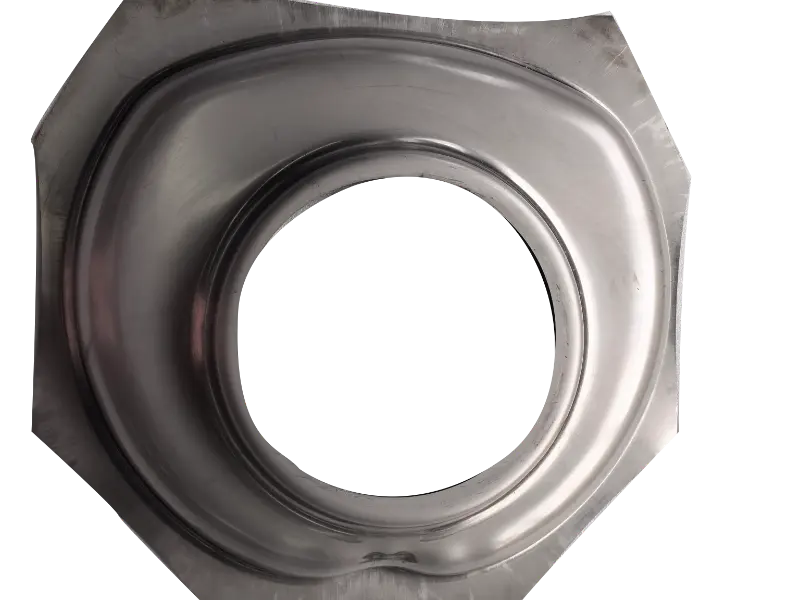

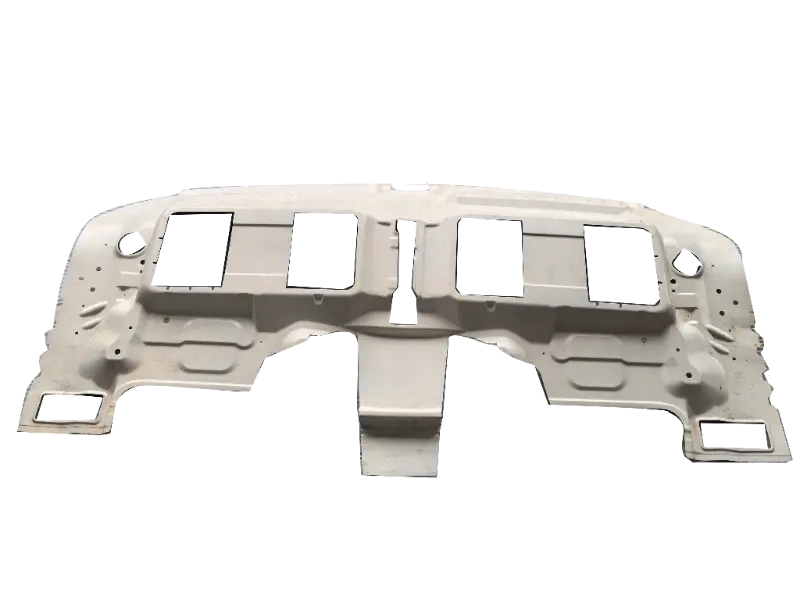

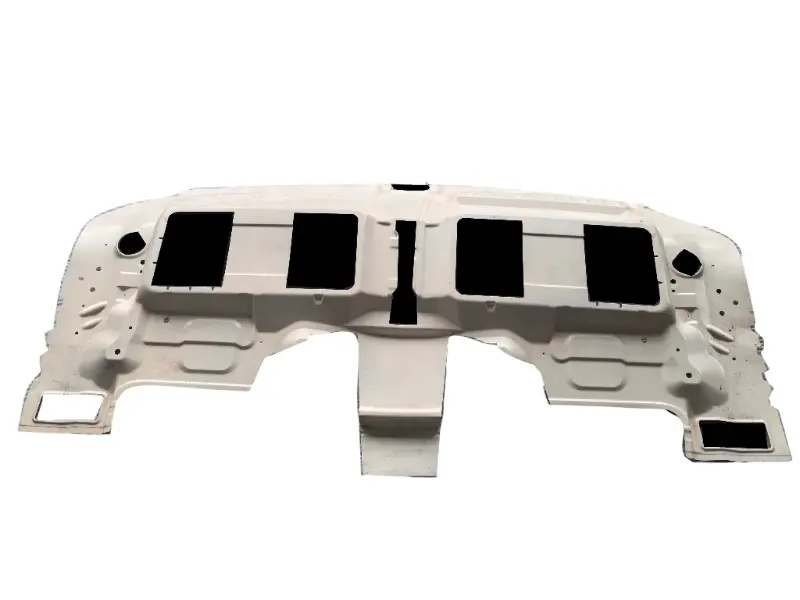

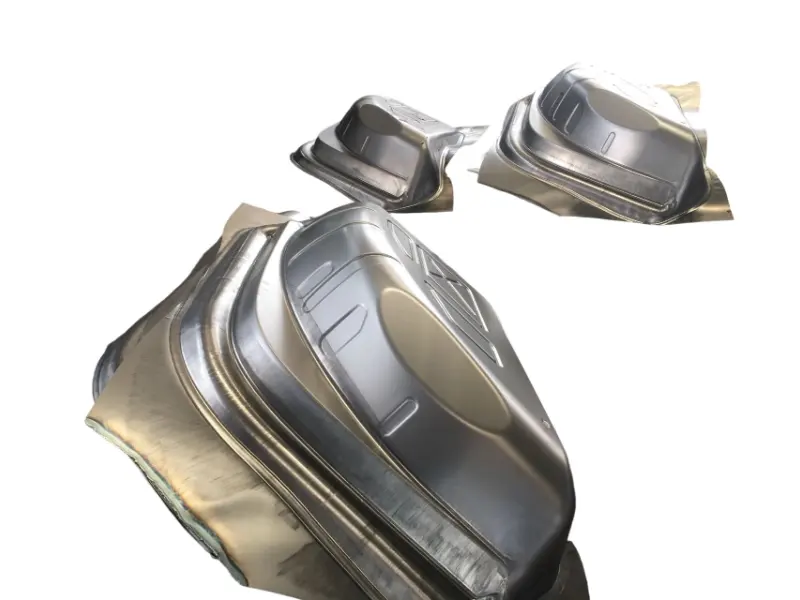

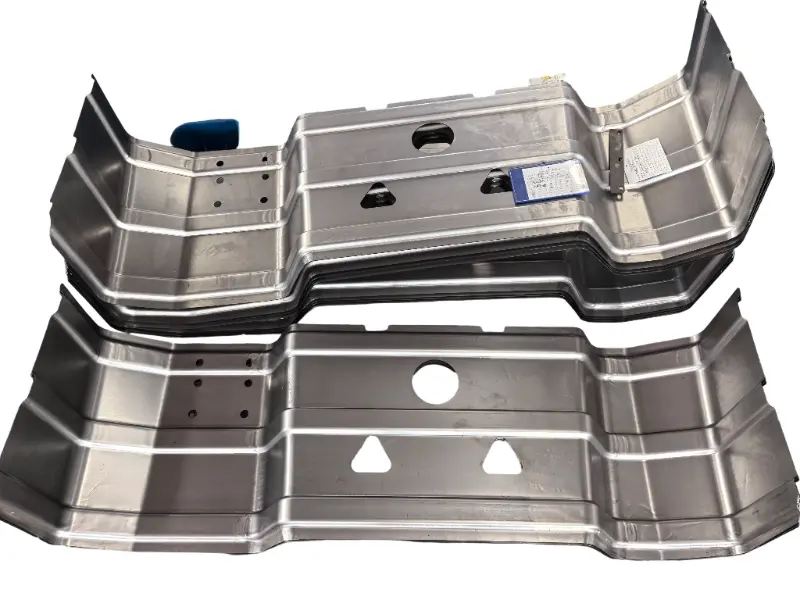

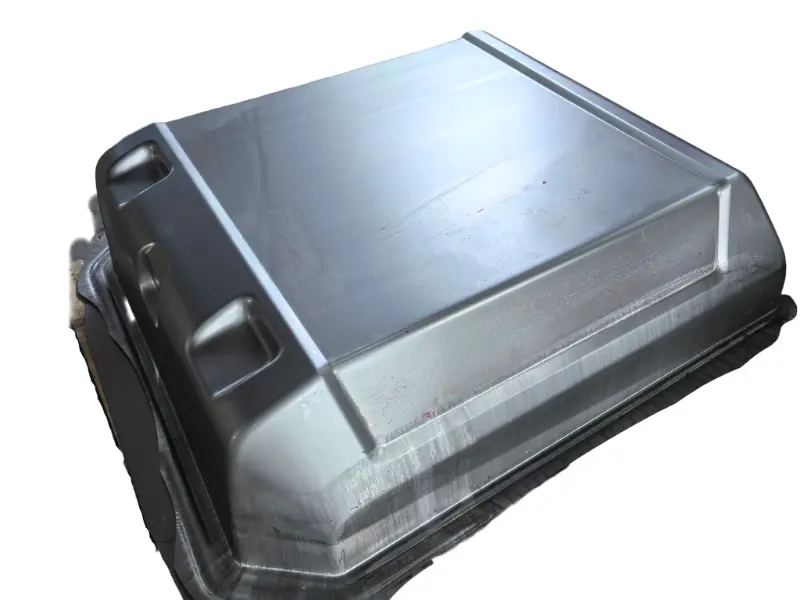

Stamped parts are metal components with specific shapes, sizes, and accuracies made from metal sheets (such as steel plates, aluminum plates, copper plates, etc.) or strips through stamping processes (using presses and molds to apply external force to the metal material, causing plastic deformation or separation). The core advantages are "high forming efficiency, stable dimensional accuracy, controllable cost, and suitable for mass production". They are the core raw materials for lightweight and standardized components in the fields of electronics, automobiles, home appliances, hardware, etc. Compared with forged parts and castings, stamped parts have significant advantages in thin-walled structure forming and mass production cost-effectiveness.

Stamped Parts

steel:DC01 / DC04 / DC06 / SPCC / SPCD / Q235 / Q355 / Copper / Aluminum, etc.

Product Description:

Product Usage

Stamping parts are widely used in fields that require high component standardization, cost control, and production efficiency due to their characteristics of “efficient batch forming, lightweight, and stable precision”. The specific uses are as follows:

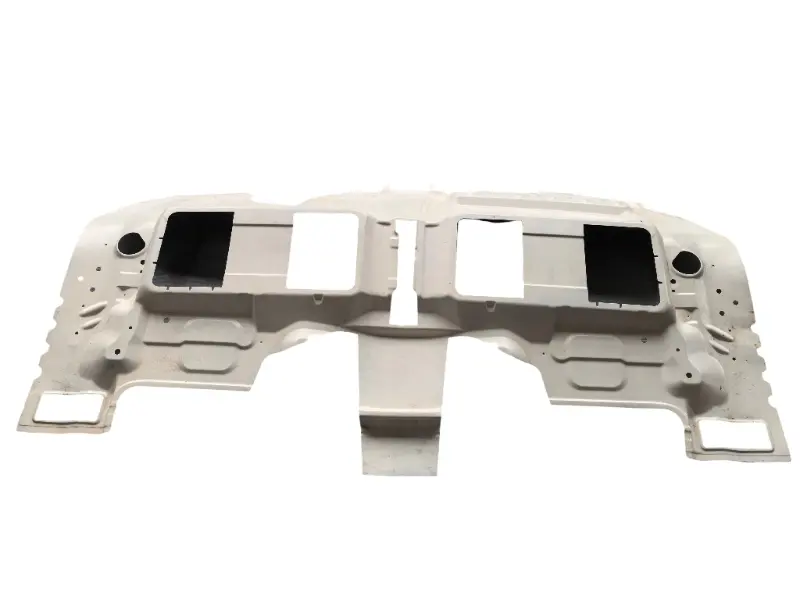

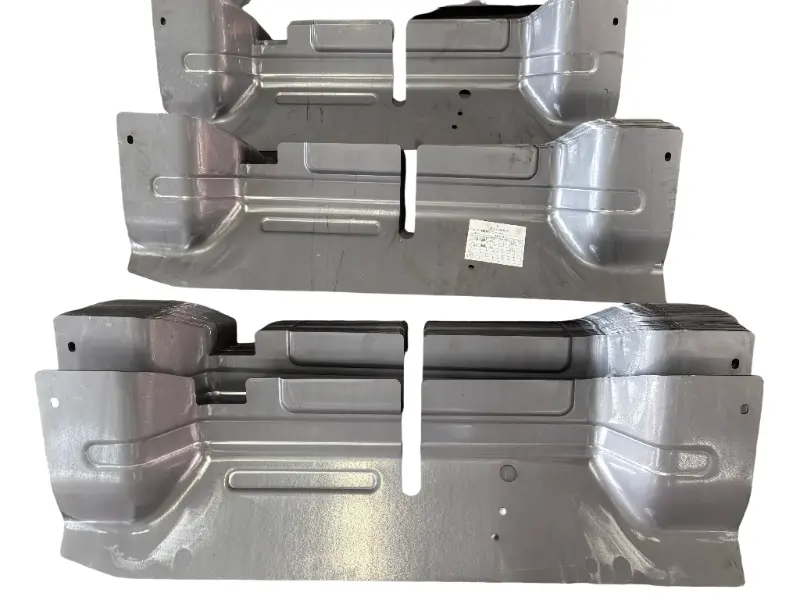

1 Automotive field

The automotive industry is the largest application scenario for stamped parts, accounting for 40% -50% of the total demand for stamped parts. A sedan requires 500-800 stamped parts, covering the body, chassis, power system, electronic system, etc

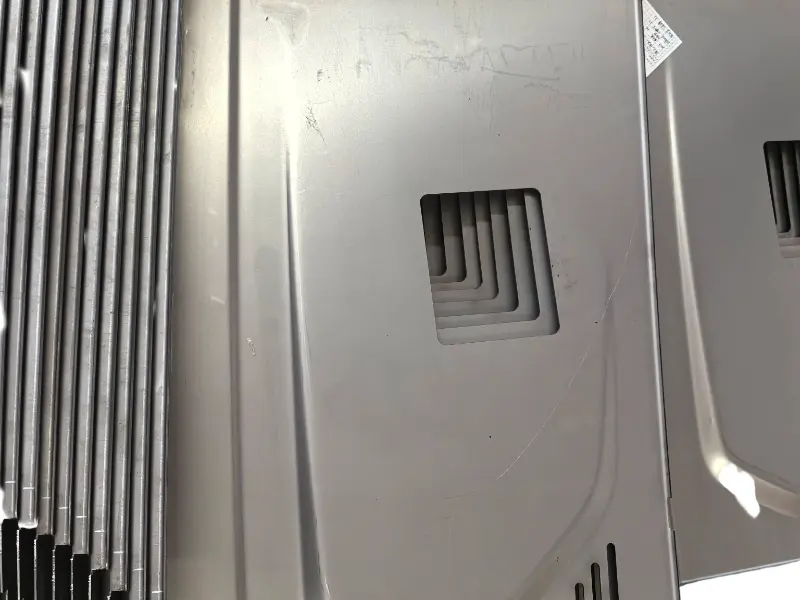

2.In the field of home appliances and consumer electronics, the precision, appearance, and cost requirements for stamped parts are strict, mainly used for the production of shells, internal structural parts, and functional components.

3.In the field of electronics and electrical appliances, stamping parts are characterized by “miniaturization and high precision”, mainly used for producing conductive components, connecting components, and heat dissipation components.

4. In the field of hardware and daily necessities, there is a high demand and a wide variety of stamping parts, mainly used for the production of tools, fasteners, and daily necessities.

5. Medical devices and aerospace industry

The medical device and aerospace fields have strict requirements for the accuracy, material safety, and corrosion resistance of stamped parts.