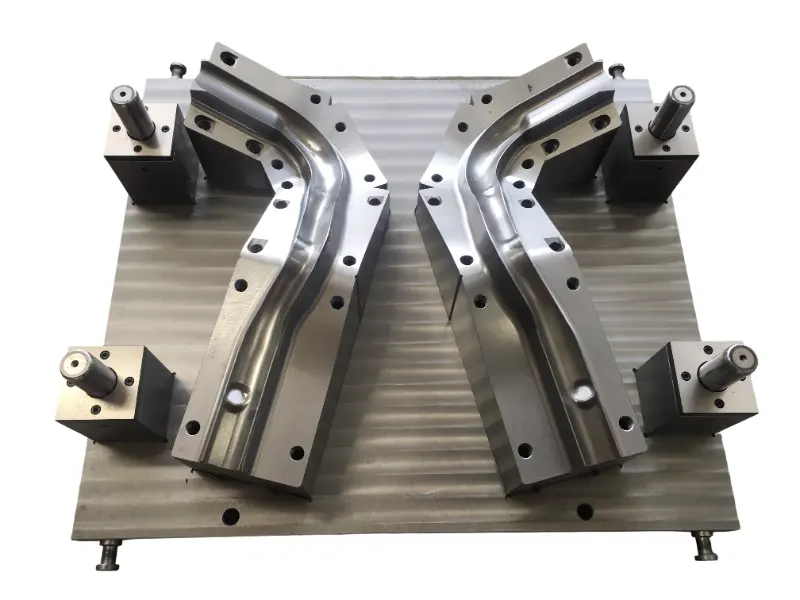

Tube material expansion mold is a professional tool designed for high-pressure expansion processing of metal tubes (such as steel pipes, aluminum pipes, copper pipes). Its core advantage lies in "precise control of the inner and outer shape of the tube material, achieving integrated molding of complex tube parts, and reducing welding processes". It is a key equipment for manufacturing special-shaped pipe fittings (such as automotive exhaust pipes, hydraulic oil pipes, and aviation conduits) in the fields of automobiles, aerospace, hydraulic equipment, etc.

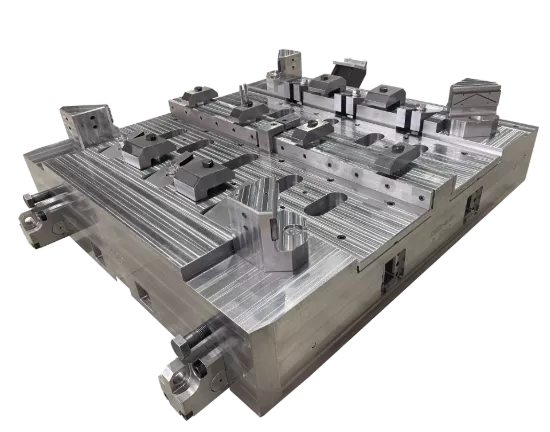

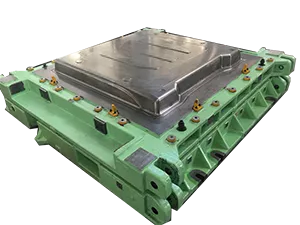

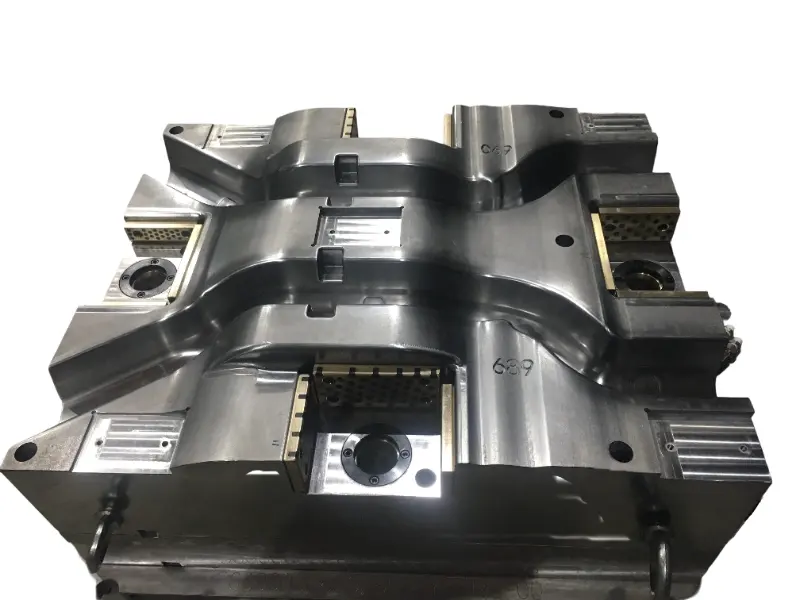

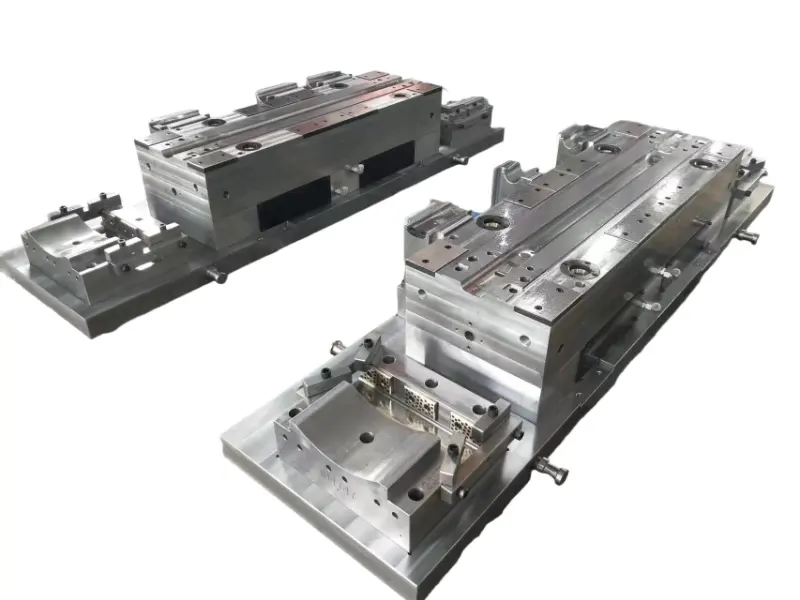

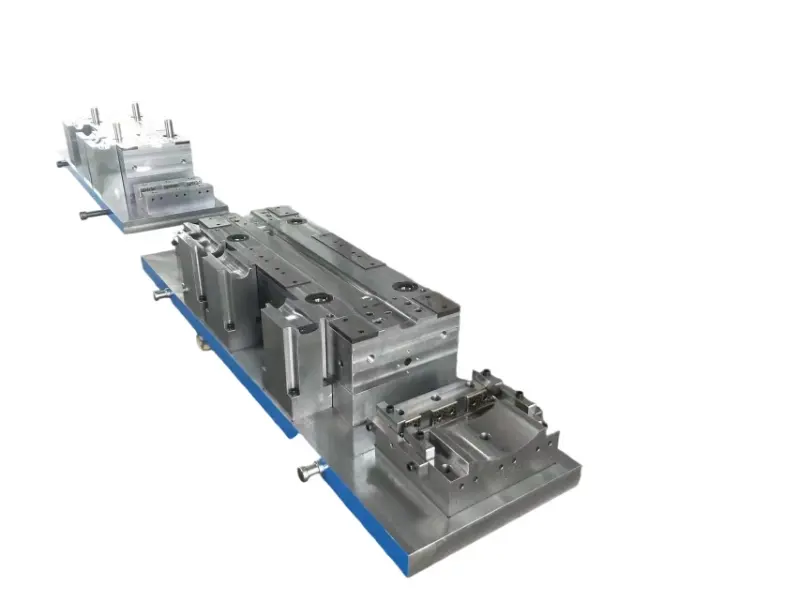

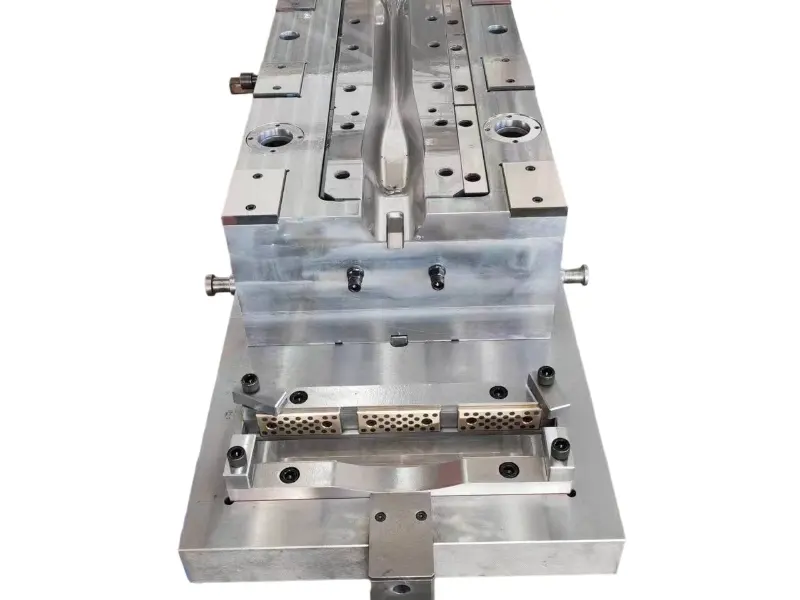

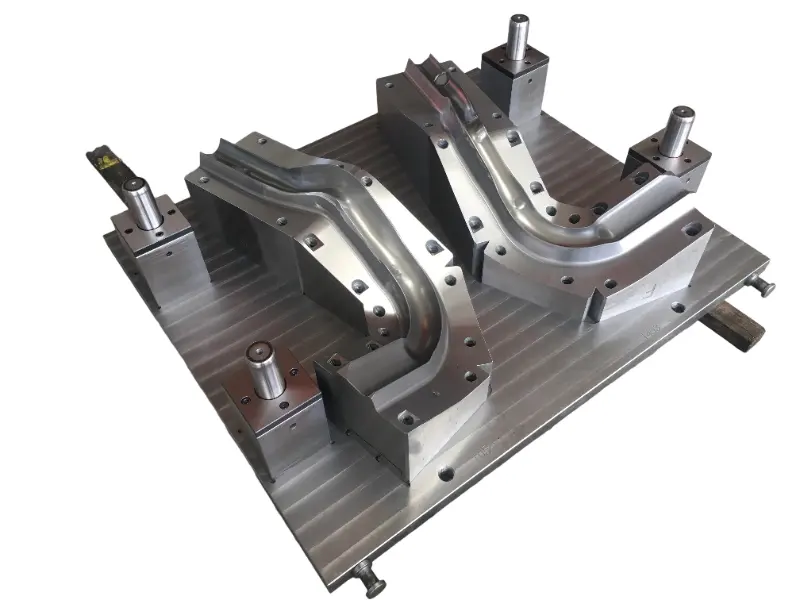

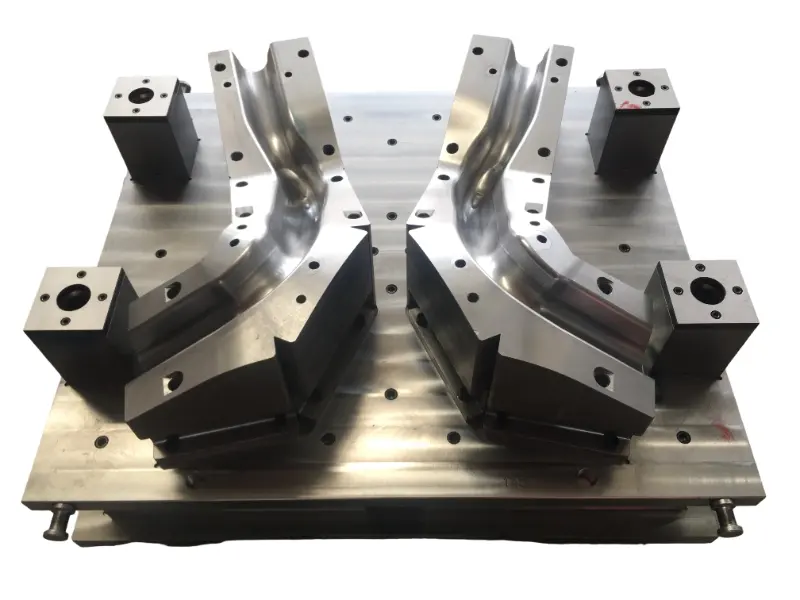

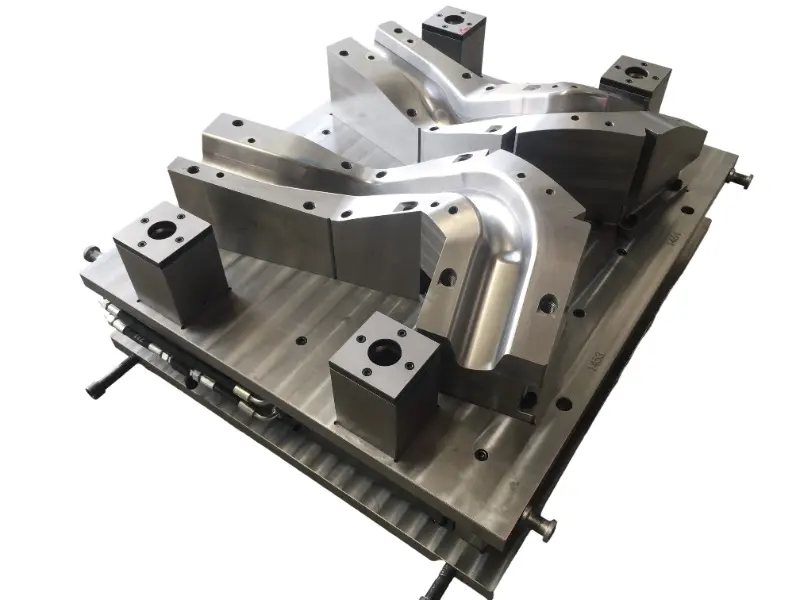

From a structural perspective, the tube material expansion mold adopts a composite design of "cavity constraint+internal pressure drive", mainly composed of an outer mold, an internal expansion mechanism, a sealing component, a positioning device, and a demolding mechanism. The outer mold is usually a split structure (such as left and right split molds, upper and lower closed molds), and the internal processing has a cavity that perfectly matches the final shape of the pipe (including complex structures such as protrusions, bends, and variable diameters). The cavity is reserved with reasonable molding gaps and exhaust holes to ensure that the pipe material can fully fit the cavity under high pressure, while avoiding molding defects caused by gas residue.

Tube material expansion mold

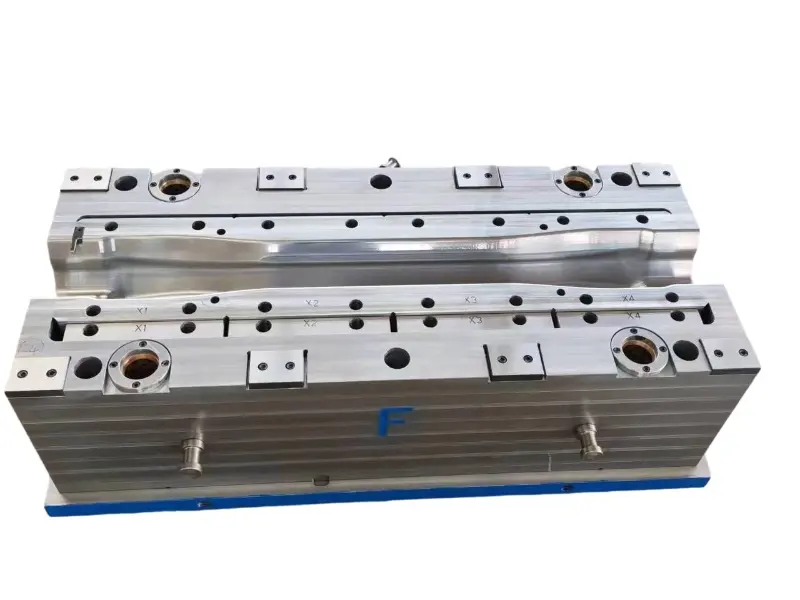

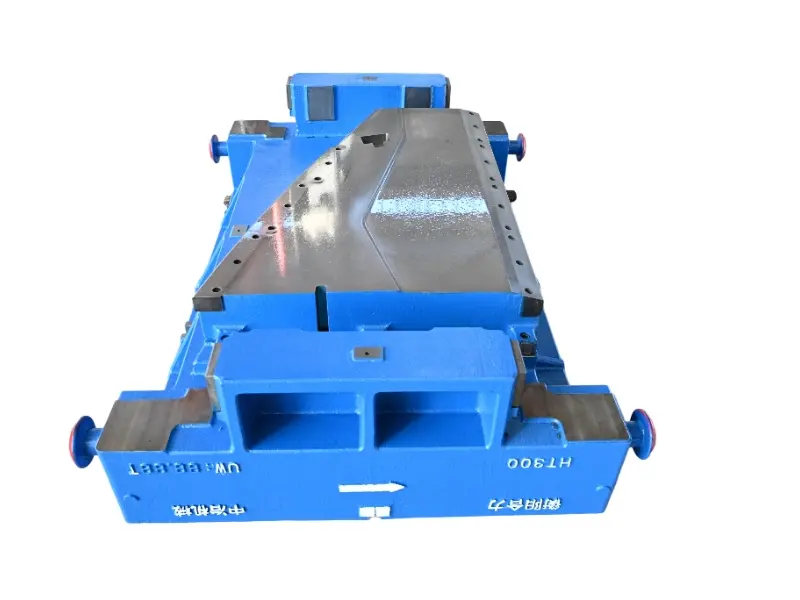

steel:HT200,HT300,ZG270-500,ZG310-570,Cr12MoV, SKD11, DC53, ect.

Product Description:

Product Usage

The pipe expansion mold, with its characteristics of “integrated molding of complex pipe fittings, high precision, and high efficiency”, is widely used in fields that require high structural complexity and dimensional accuracy of pipe parts. Its specific uses are as follows:

1.Manufacturing of irregular pipe fittings in the automotive industry

This is the most core application scenario of pipe expansion molds, mainly used for producing irregular pipe fittings for automotive power systems, chassis systems, and exhaust systems. For example, the exhaust pipe of a car (including the casing of a three-way catalytic converter) can be formed by integrating the variable diameter, bending, and protruding structure of the exhaust pipe through a pipe expansion mold, avoiding the problems of weld corrosion and air leakage caused by traditional welding processes, while reducing the number of parts and improving the overall strength and sealing of the exhaust pipe; The hydraulic brake oil pipe and steering oil pipe of the car chassis can be precisely controlled by the mold to ensure the uniformity of the inner diameter and wall thickness of the oil pipe (deviation ≤ 0.1mm), ensuring stable transmission of hydraulic oil under high pressure and avoiding the risk of pipe bursting caused by uneven wall thickness of the oil pipe; The battery cooling pipes and motor cooling pipes of new energy vehicles are formed through expansion molds with multi-channel cooling pipes, which can increase the flow area of the cooling medium, improve heat dissipation efficiency, and meet the high-temperature heat dissipation needs of new energy vehicle batteries and motors; In addition, the frame tubes and anti-collision beam tubes of the car body can also be locally thickened or reduced in diameter through expansion molds, which can improve structural strength while reducing weight and adapt to the trend of lightweight design in automobiles.

2.Precision conduit manufacturing in the aerospace field

In the aerospace field, pipe expansion molds are used to produce precision pipe fittings such as aircraft engine fuel pipes, hydraulic system pipes, and spacecraft propulsion system pipes. These types of pipe fittings are often made of difficult to deform materials such as titanium alloys and high-temperature alloys, and require complex bending angles (such as 90 °, 135 °) and variable diameter structures. Through the “thermal expansion type+flexible internal expansion medium” process, the mold can uniformly deform the pipe material. At the same time, integrated molding avoids welding joints, reduces the risk of pipe failure, and ensures the safety of aerospace flight.

3.Manufacturing of hydraulic and pneumatic equipment pipelines

In the field of hydraulic and pneumatic equipment, pipe expansion molds are used to produce hydraulic valve block connecting pipes, cylinder inlet and exhaust pipes, high-pressure oil pipes and other pipeline components. The connecting pipe of the hydraulic valve block needs to be accurately matched with the valve block interface. The flange and step structure of the pipe end can be integrated and formed through mold expansion, reducing the number of sealing gaskets required for connecting with the valve block and lowering the probability of hydraulic oil leakage; The mold controls the expansion pressure and the thickness of the pipe material to make the inner wall of the oil pipe smooth and free of impurities, avoiding hydraulic oil pollution or oil pipe wear caused by rough inner walls, and extending the service life of the hydraulic system; The inlet and exhaust pipes of pneumatic equipment are adjusted in diameter and branching structure through expansion molds, optimizing airflow channels, reducing airflow resistance, improving the efficiency of pneumatic equipment, and adapting to pneumatic systems such as machine tools and automated production lines.