Unveiling the Secrets of Forging Dies: 7 Steps to Refine Your Skills

Release time: 2025-11-07

Table of Contents

Forging dies are a fundamental tool in the metal forging industry, and their quality and craftsmanship directly affect the strength, precision, and lifespan of products. Whether manufacturing automotive parts, construction machinery components, or hardware tools, high-quality forging dies play an indispensable role. To help more practitioners improve their processing skills, Zhongye will guide you through the forging die manufacturing process and help you quickly refine your die manufacturing skills through 7 key steps.

Step 1: Defining Product Requirements and Technical Parameters

Before starting die design, it is essential to fully understand the structure, dimensions, tolerances, and application scenarios of the target product. This stage involves analyzing drawings and material properties to determine suitable forging die materials and forming methods, laying the foundation for subsequent processes.

Step 2: Forging Die Design and Structural Planning

Die design is the core of the entire manufacturing process. Designers need to combine stress analysis and streamline simulation to rationally plan the die cavity shape, ensuring smooth metal flow and reducing the risk of wrinkles and cracks. Professional software-aided design (CAD/CAE) can improve the accuracy and efficiency of mold design.

Step 3: Material Preparation and Heat Treatment

Material selection affects the wear resistance and stability of the mold. Commonly used materials include alloy steel and high-toughness steel. Hardness is increased through pretreatment, quenching, and tempering, giving the mold better fatigue resistance. Scientific heat treatment can significantly extend the service life of forging dies.

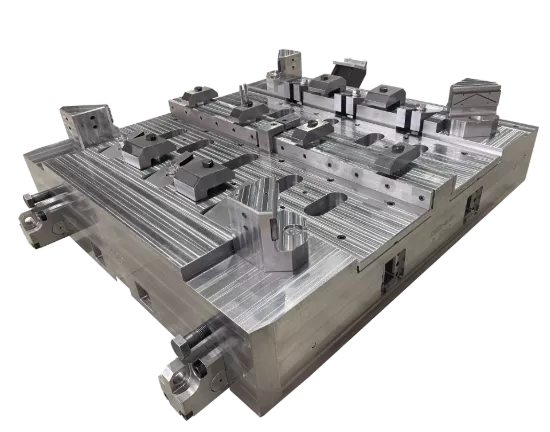

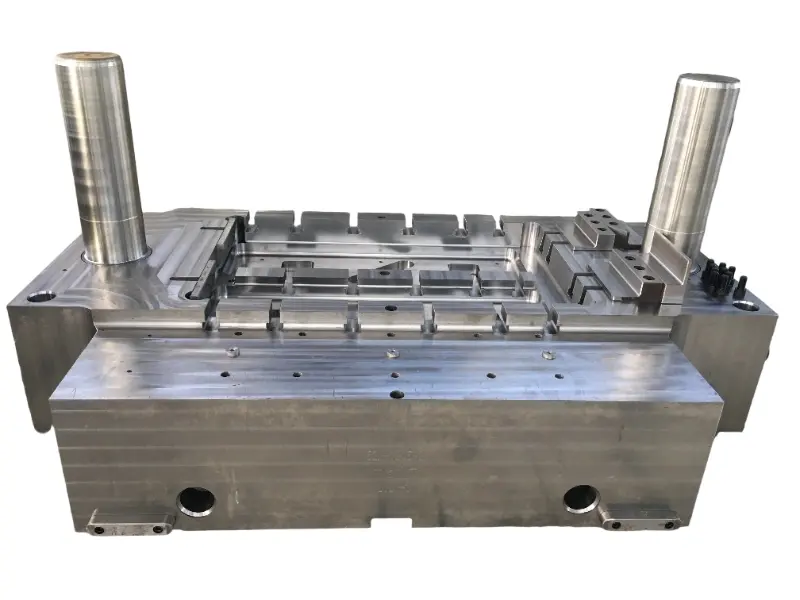

Step 4: Machining and Cavity Machining

The machining stage typically uses CNC machine tools, milling, and EDM to perform rough and finish machining on the die blank. This process requires strict control of machining errors to ensure the forging die’s closing accuracy, providing a guarantee for stable mass production later.

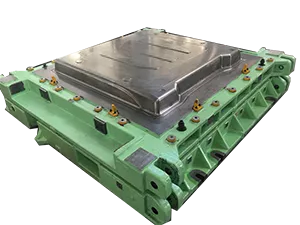

Step 5: Assembly and Correction

The machined mold components are assembled, and the clearances of each part are checked. To ensure a smooth forging process, the friction surfaces need to be ground and polished to give the mold better surface quality.

Step 6: Trial Die Testing and Forging Test

Trial die testing is a crucial step in verifying the rationality of the forging die design. By observing the metal forming state through small-batch forging tests, if incomplete filling or surface defects are observed in the billet, the die cavity or processing parameters must be adjusted promptly.

Step 7: Maintenance and Upkeep

The final step is proper die maintenance and upkeep, such as regular cleaning, applying rust-preventive oil, and monitoring wear. Good maintenance not only reduces the risk of scrap but also lowers production costs and enhances the company’s competitiveness.

Through these seven steps, you should now have a more systematic understanding of the forging die manufacturing process. Mastering the process methods, selecting high-quality materials, and strictly adhering to processing standards are key to improving the quality and production efficiency of forging dies. In the future, with the support of intelligent manufacturing and CNC technology, the forging die industry will usher in more innovation and opportunities.

If you would like to learn more about customized forging dies, processing solutions, or forging process optimization, please contact Zhongye Machinery. We are a professional forging die manufacturer and will provide you with the most comprehensive solutions.