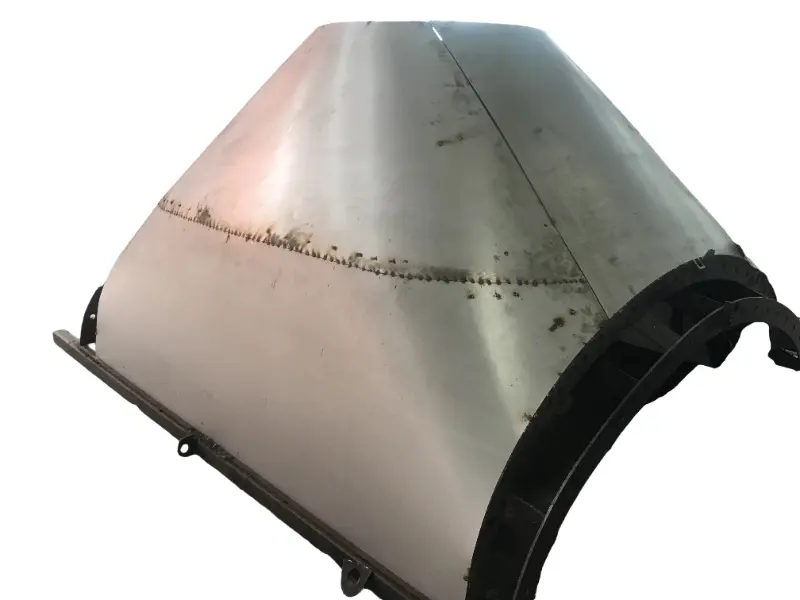

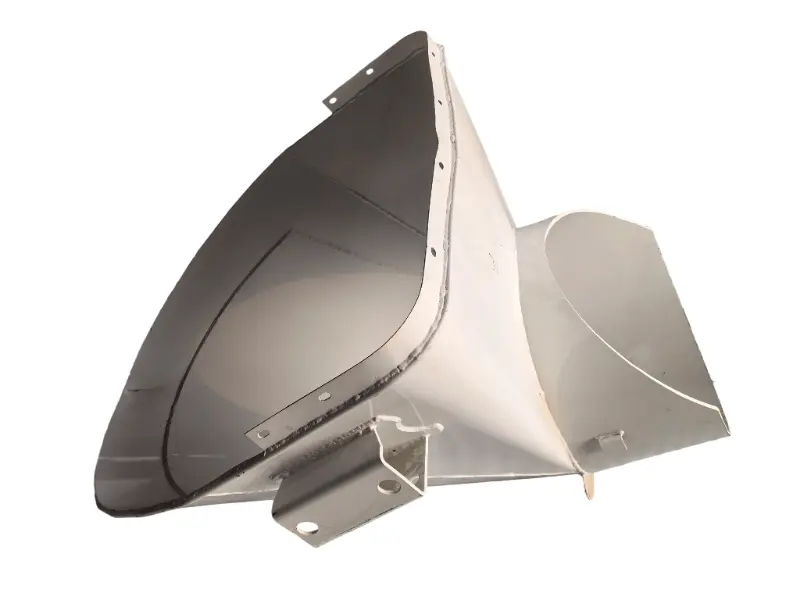

Welded parts are metal structural components with specific functions that are connected through welding processes (using heating, pressure, or a combination of both, with or without filling materials, to achieve atomic bonding between two or more metal components). The core advantages of welded parts are "the ability to splice complex structures, high material utilization, and adaptability to the manufacturing of large-sized/irregular components". They are the core components of large load-bearing and frame like components in engineering machinery, ships, steel structures, pressure vessels, and other fields. Compared with integral forged parts and castings, welded parts have irreplaceable advantages in manufacturing flexibility, cost control, and the realization of large-span structures.

Welded Parts

steel:DC01 / DC04 / DC06 / SPCC / SPCD / Q235 / Q355 / , etc.

Product Description:

Product Usage

Welding parts are widely used in fields that require high structural strength, size scale, and manufacturing cost due to their characteristics of “complex structure splicing, large size adaptation, and flexible material combination”. The specific uses are as follows:

1 In the field of construction machinery, it is the core application scenario for welded parts, accounting for 30% -40% of the total demand for welded parts. It is mainly used to manufacture large structural parts that can withstand heavy loads and impacts.

2. Ship and Ocean Engineering Field

Welding components in the fields of ship and ocean engineering must withstand seawater corrosion and wind and wave impact, with strict requirements for welding quality and corrosion resistance.

3.In the field of pressure vessels and chemical equipment, welded parts in the pressure vessel industry need to withstand high temperatures, high pressures, and corrosive media, with extremely high requirements for welding quality and safety.

4. General mechanical equipment industry, such as equipment bed, frame, structural components, etc.

_WH_800x600px.webp)